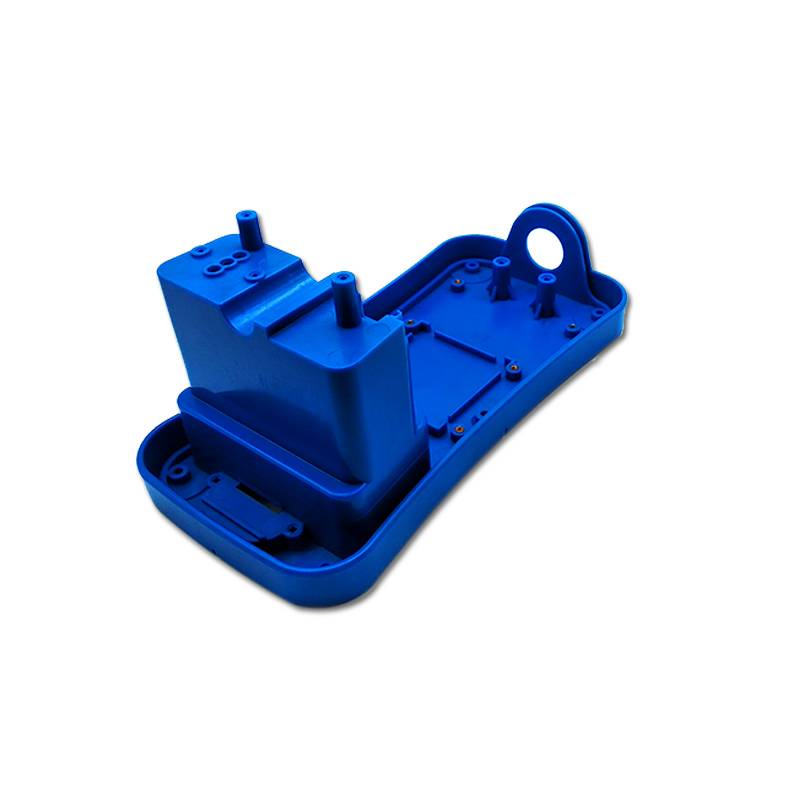

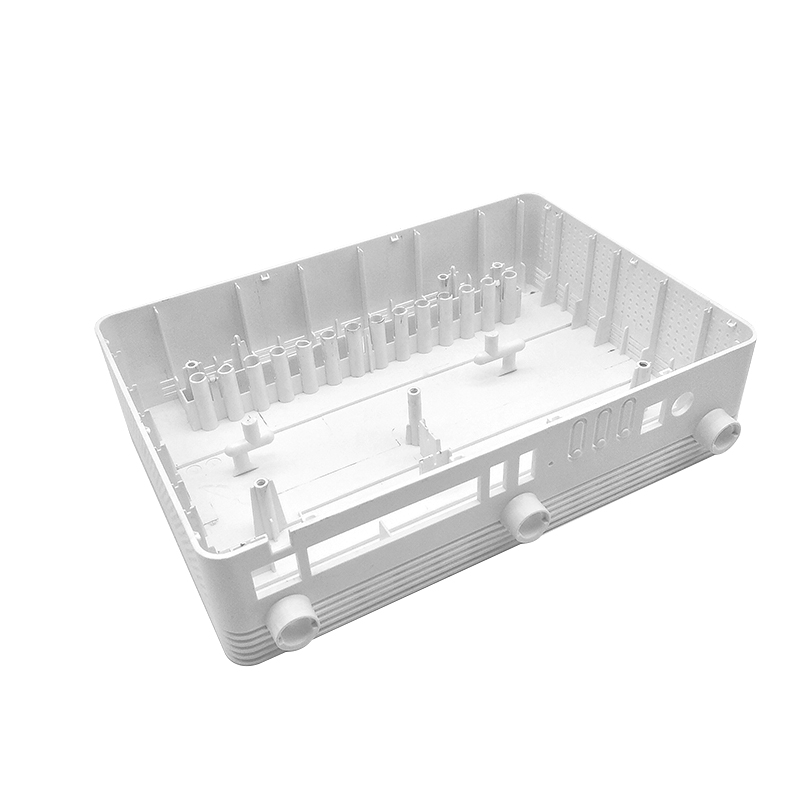

Tooling - Factory, Suppliers, Manufacturers from China

Every single member from our large efficiency revenue team values customers' wants and company communication for Tooling, Plastic Auto Parts, Oem Plastic Parts, Auto Mold,Plastic Mould. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits. The product will supply to all over the world, such as Europe, America, Australia,Malta, The Swiss,Malawi, Washington.We are fully aware of our customer's needs. We provide high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Related Products