Injection Production - China Factory, Suppliers, Manufacturers

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Injection Production, Injection Tooling, Air Conditioner Plastic Injection Mould, Plastic Molded Parts,Plastic Gear. Welcome friends from all over the world come to visit, guide and negotiate. The product will supply to all over the world, such as Europe, America, Australia,Cyprus, Naples,St. Petersburg, Morocco.Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

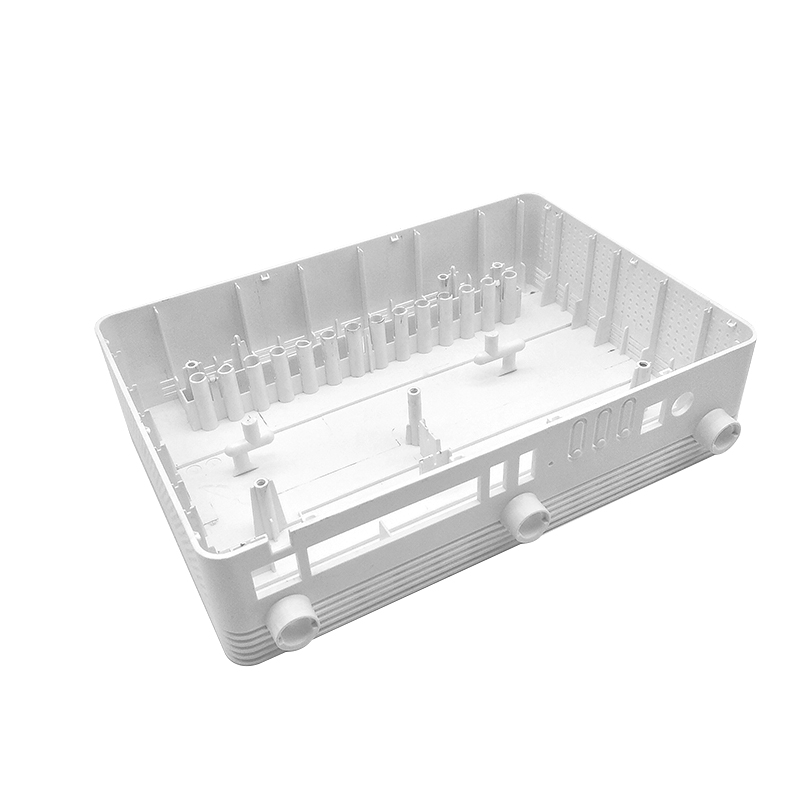

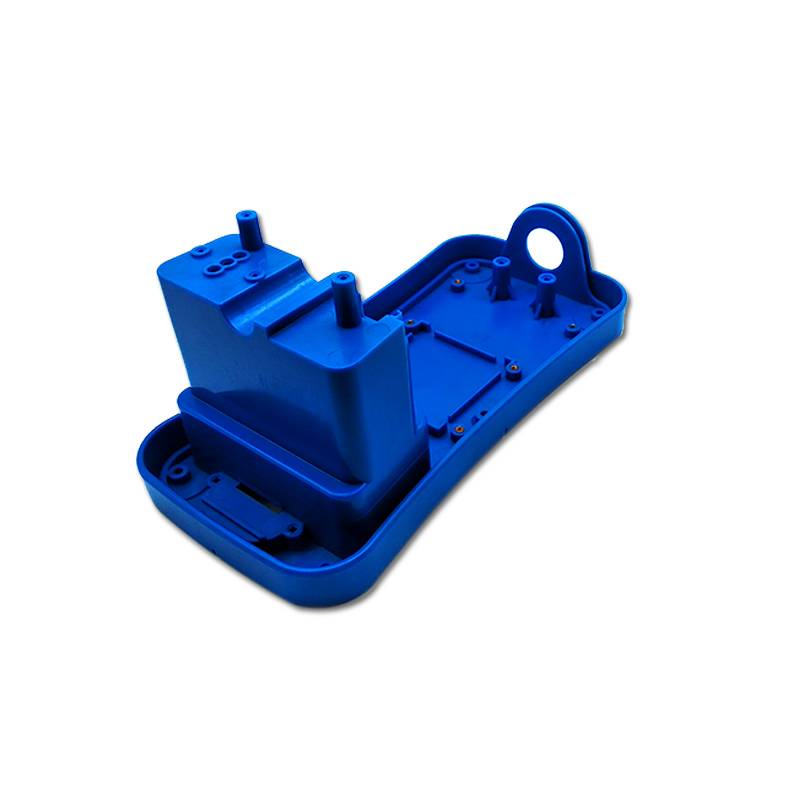

Related Products