All successful parts start with a well-designed mold. This complex and precise process determines part manufacturability and lifecycle costs in addition to taking into account the key components of mold design while adhering to a part’s unique specifications.

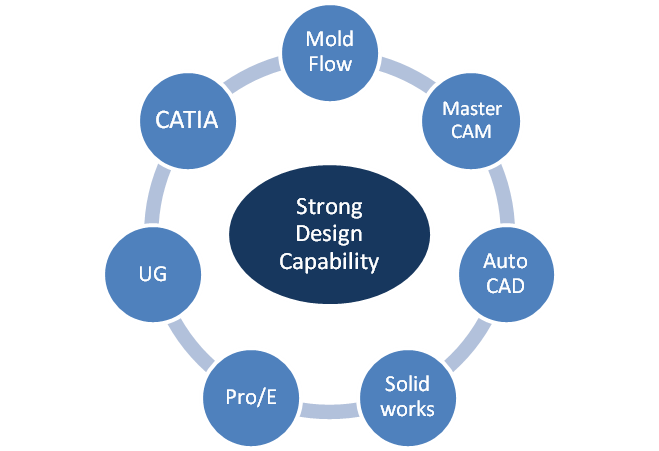

Considered one of our Five Keys to Success, proper mold design and mold building will help reduce costs, increase quality and optimize performance. Chapman Maker supports a variety of software design applications, including UG, PROE, CAD, SOLIDWORKS and so on. Of course, we can, also, provide you with a variety of mold design standards: DME, HASCO, MEUSBURGER, LKM,as well as mold flow analyses to evaluate all mold designs and parts prior to development.

Chapman Maker molding facilities offer flexibility in running all types of thermoplastic materials. We specialize in manufacturing products for a broad range of applications as well as for specific industries including the automobile,medical, electronic equipment, connectors, industrial, defense, transportation, and consumer markets.

Chapman Maker owns injection machines from 90 to 600 tons. We can assist you in optimizing and improving your product design in order to achieve the best possible results and meet your component requirements.

Core Molding Capabilities

1.Large complex Molding

2.Small precision Molding

3. Insert molding and Over molding

4.LSR & Rubber molding

5.Moldbase machining

Our team at Chapman Maker work closely with our business partners to provide added value services for industry leading complex components. Below are a few of these value added services:

• Multi-Component Assemblies

• Mold Repairs & Maintenance

• Mold Transfer Program and Procedures

• Ultrasonic Welding

• Kanban, Stocking Programs, etc.

• Assist in Reshoring Efforts

• Part Decorating

• Custom Colors and Quick Change Color