Quick Turn Injection Molding - Manufacturers, Factory, Suppliers from China

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for Quick Turn Injection Molding, Plastic Mold Cost, Design For Manufacturing, Oem Plastic Parts,Car Parts. We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation. The product will supply to all over the world, such as Europe, America, Australia,Buenos Aires, Korea,New Orleans, Sao Paulo.With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

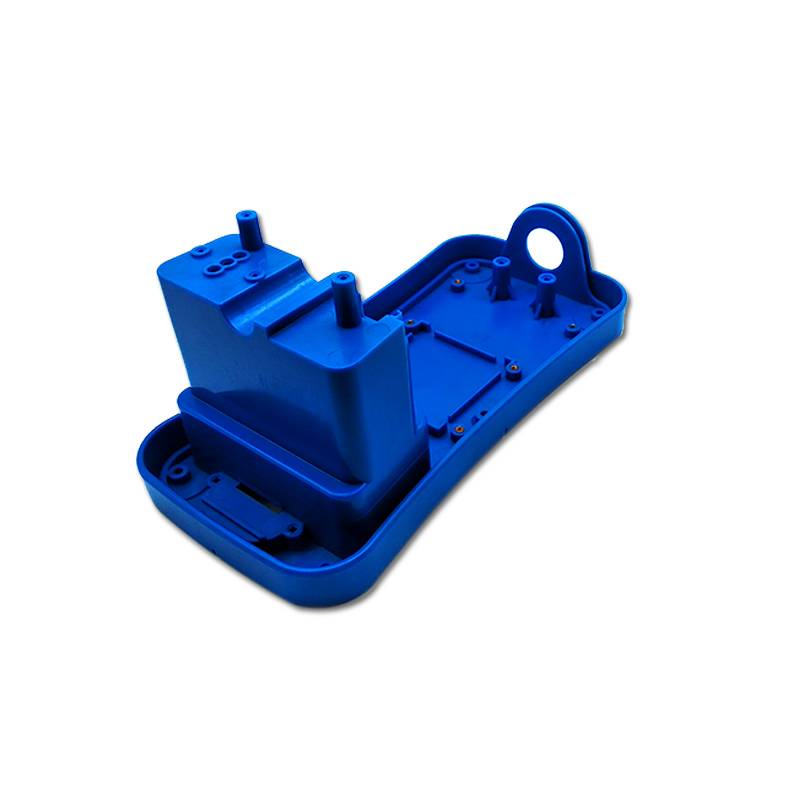

Related Products