News

-

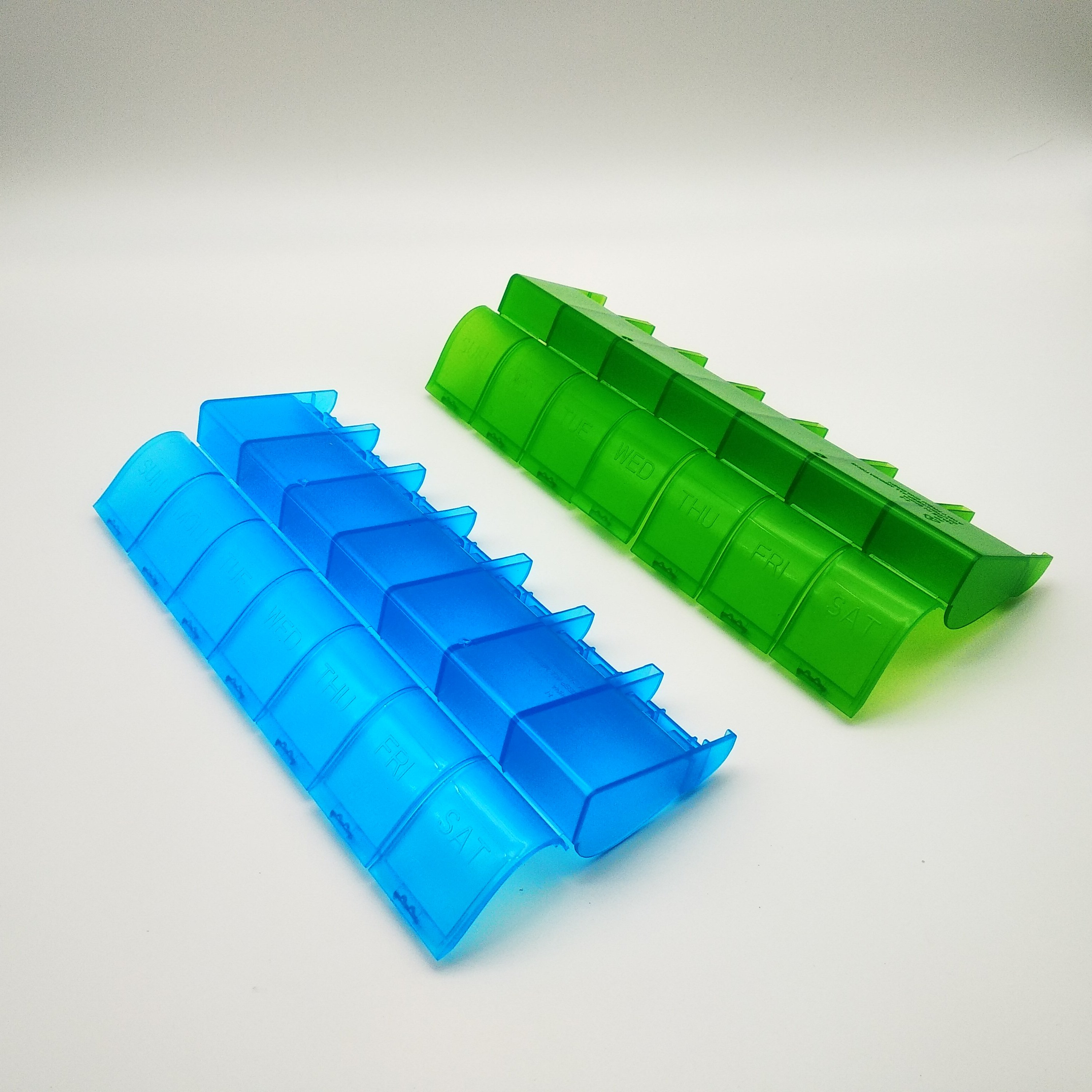

Are there different types of plastics that can be used for injection molding?

Plastic materialsare used in a wide variety of applications, and often plastics engineers work with customers to specify the best plastic for their application. This can be based on temperature, it can be based on environmental conditions, it can be fairly based on a wide range of factors that d...Read more -

How Chapman maker made plastic injection molding?

A good set of plastic molds is caused by many factors. However, each factor may affect the quality of the mold, material selection, processing equipment, processing environment and processing technology. At Chapman maker, we believe that the following six systems are the main influence , to see...Read more -

Why do mechanical parts need heat treatment

Due to the large amount of impurities in the metal in the mining process, its physical and chemical properties have serious instability in use. Through heat treatment, it can be effectively purified and its internal purity can be improved. Heat treatment technology can also strengthen its quality...Read more -

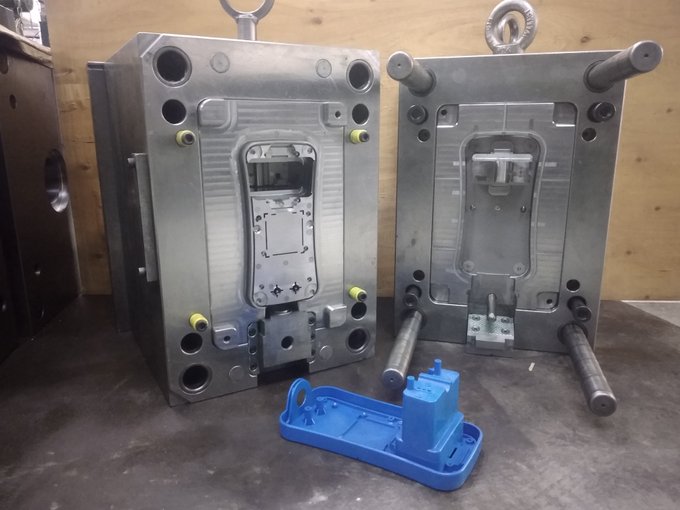

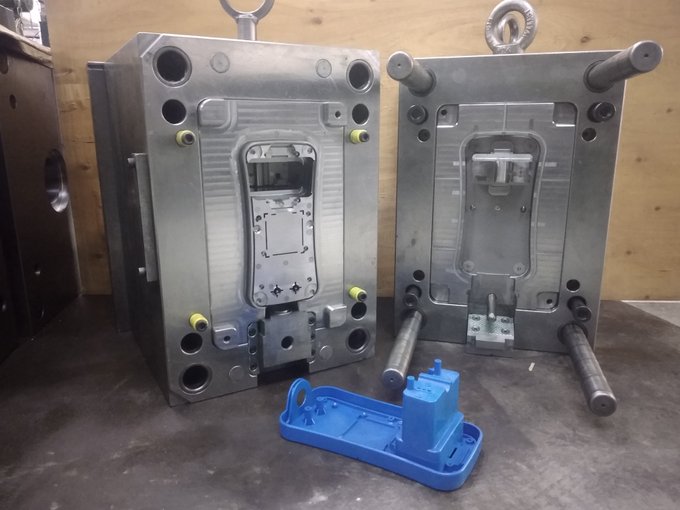

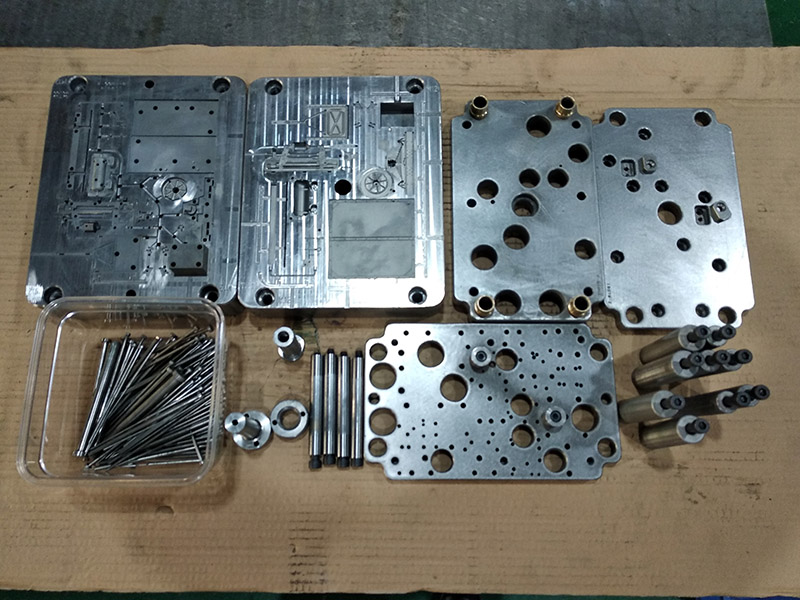

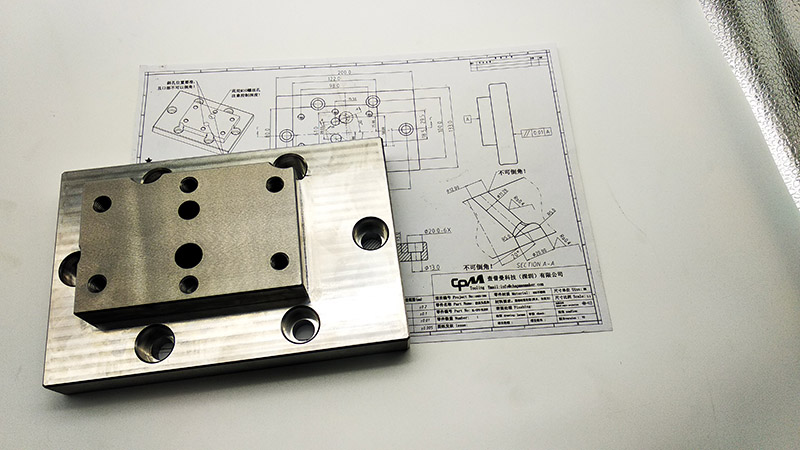

Mold making and testing

The production equipment must be verified, in order to produce the production standard before the large batch mold trial, it is necessary to have samples to adjust and control the processing conditions, and to know the best temperature and pressure conditions, as well ...Read more -

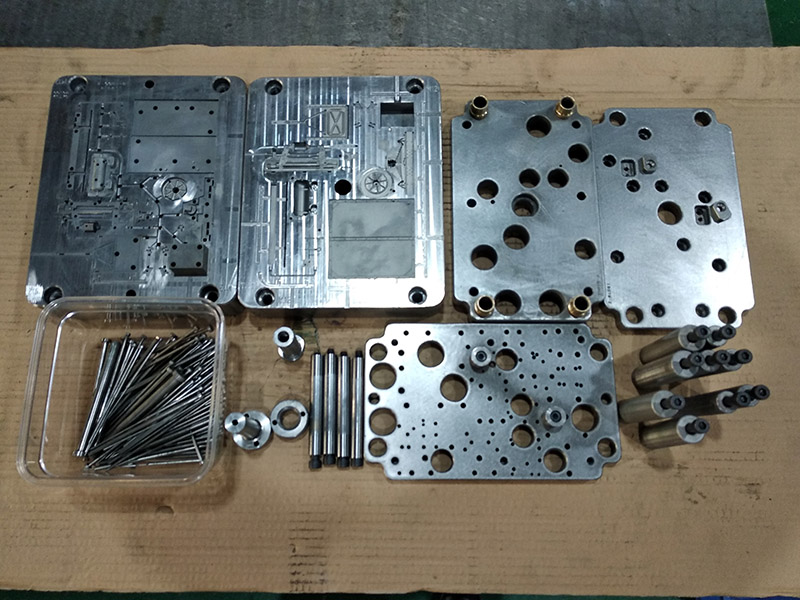

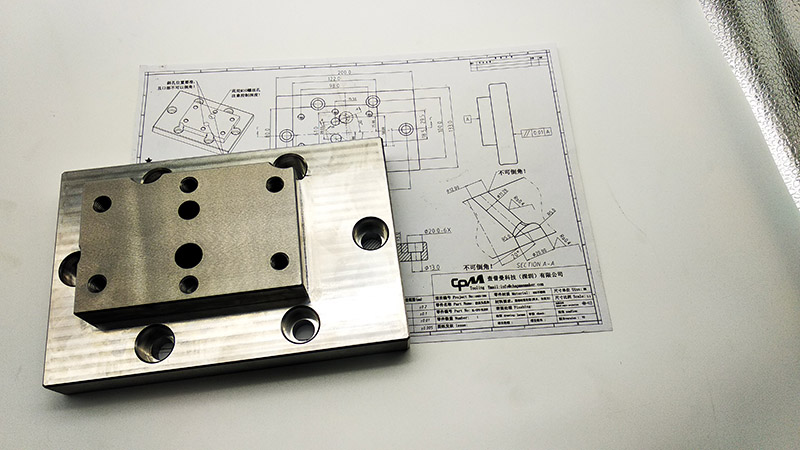

Injection mould requirements for steel

The manufacturing and processing precision requirements for manufacturing molds are relatively strict, so the manufacturing costs of manufacturing molds are in line with the standards of mold manufacturing higher in order to make the material requirements reasonable and ...Read more -

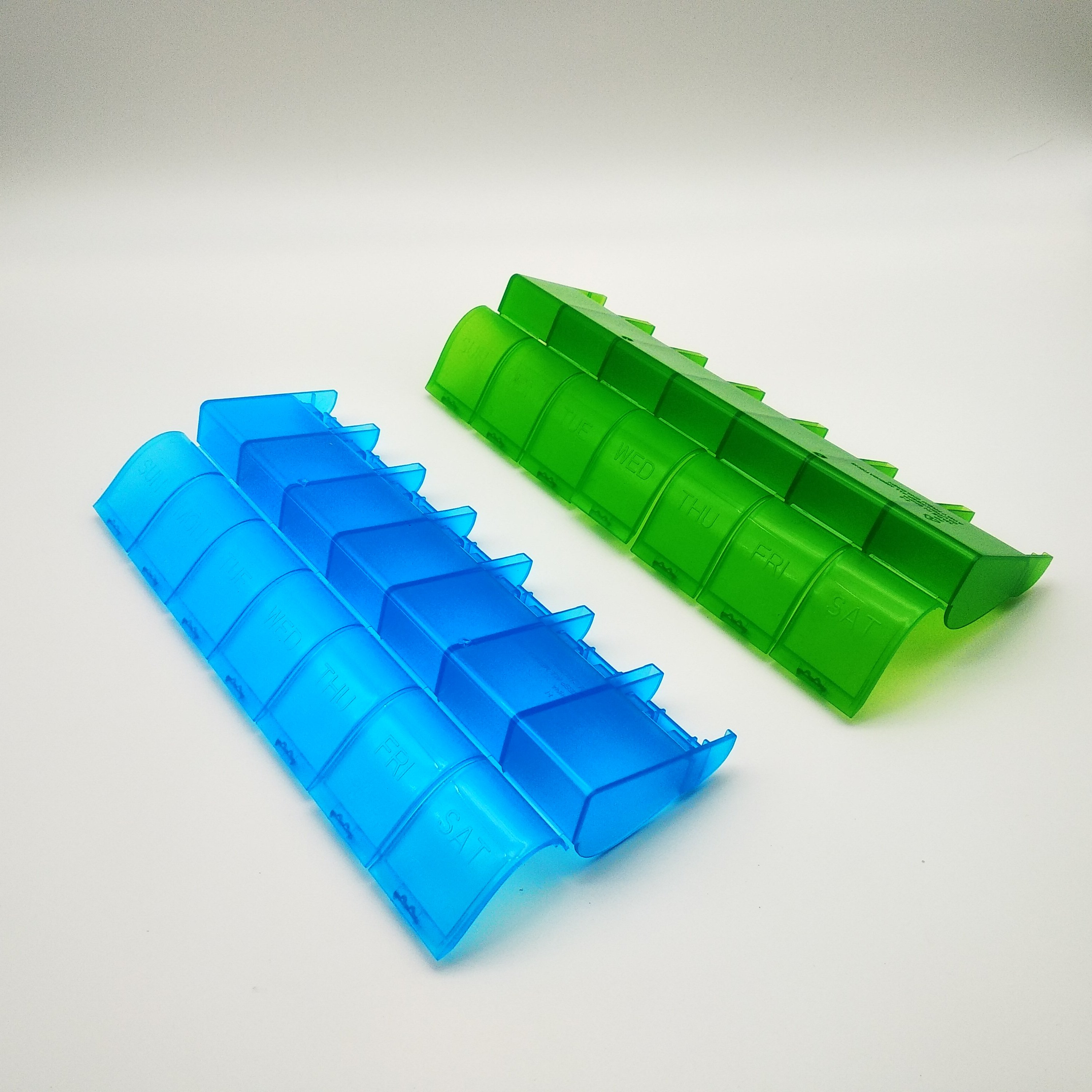

Medical Injection Mould

In the development of plastic medical devices, injection molds play a role that cannot be ignored. As a professional mold manufacturer, Chapman has provided various medical molds for domestic and foreign users over the years, such as: syringe molds, infusion bottle molds...Read more -

The advantages of plastic prototype for product designing

In Chapman maker company, the newly designed new product development generally requires a prototype to test the assembly and basic functional effects, because the newly designed product will have some deficiencies more or less, and these deficiencies can be found by making a prototype, and then s...Read more -

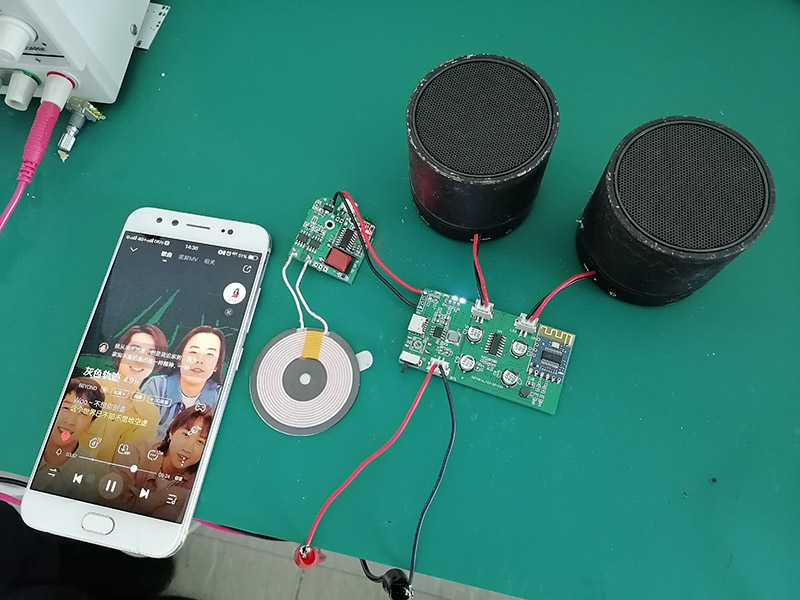

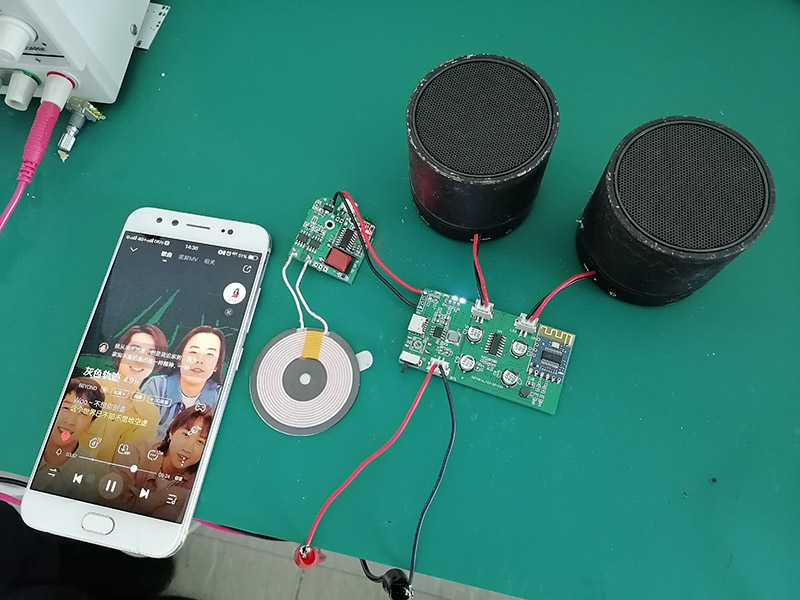

Chapman maker- One-stop product customization service

After years of development, Chapman maker has formed its own complete process and a supply chain service circle within half an hour. From product structure design optimization - 3D printing test, Rapid soft mould small quantity trial order, mold injection / hardware pro...Read more -

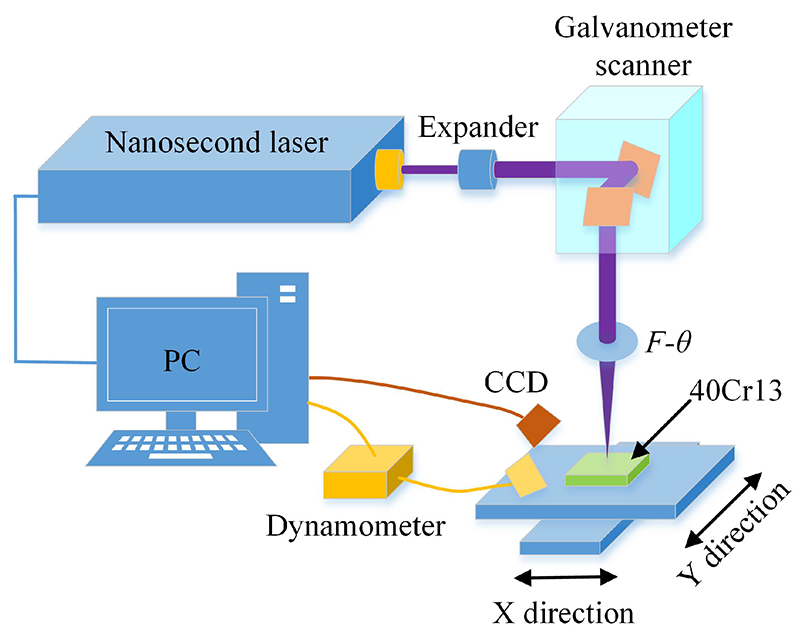

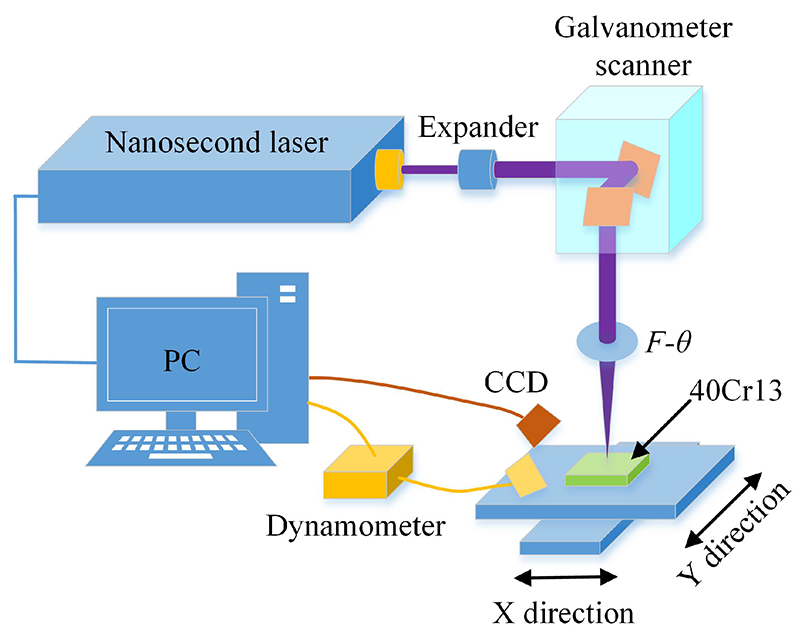

Application of laser processing in mold industry

In the mold industry processing, the laser can be used in many wide-ranging aspects. To give three examples: laser cutting, laser engraving and laser welding. laser cutting It can be accurate to 0.04mm. For high-precision process cutting, laser cutting is one of the first choices. Wire cutting v...Read more -

CNC machining of hardened and quenched moulds

In recent years, many mold factories have used hardened and quenched materials to produce high-precision molds, and the CNC machining of hardened and quenched materials requires much higher milling cutters, processing technology, and programming points than the processing of general mold material...Read more -

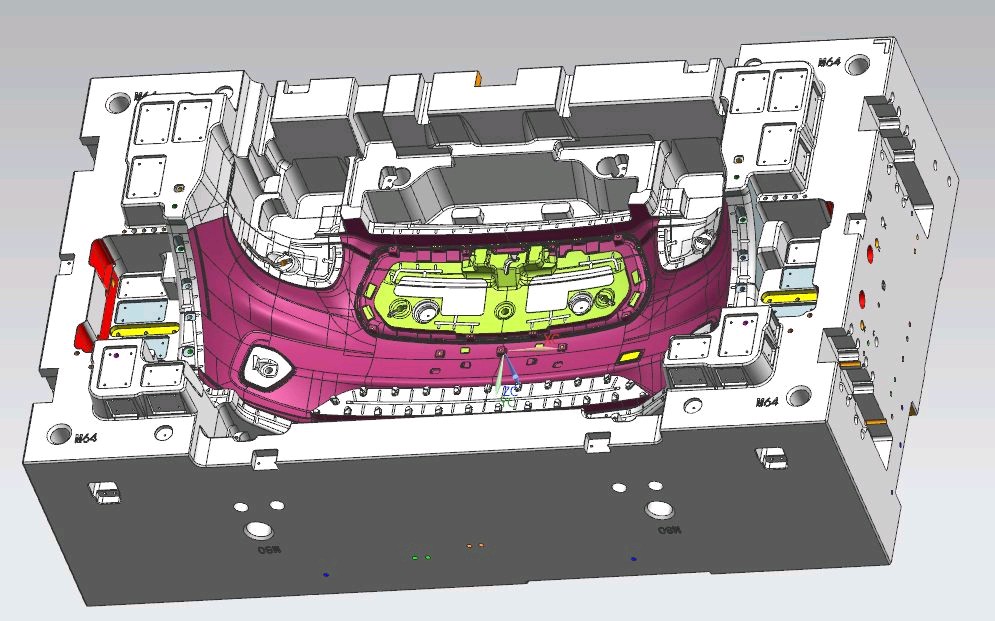

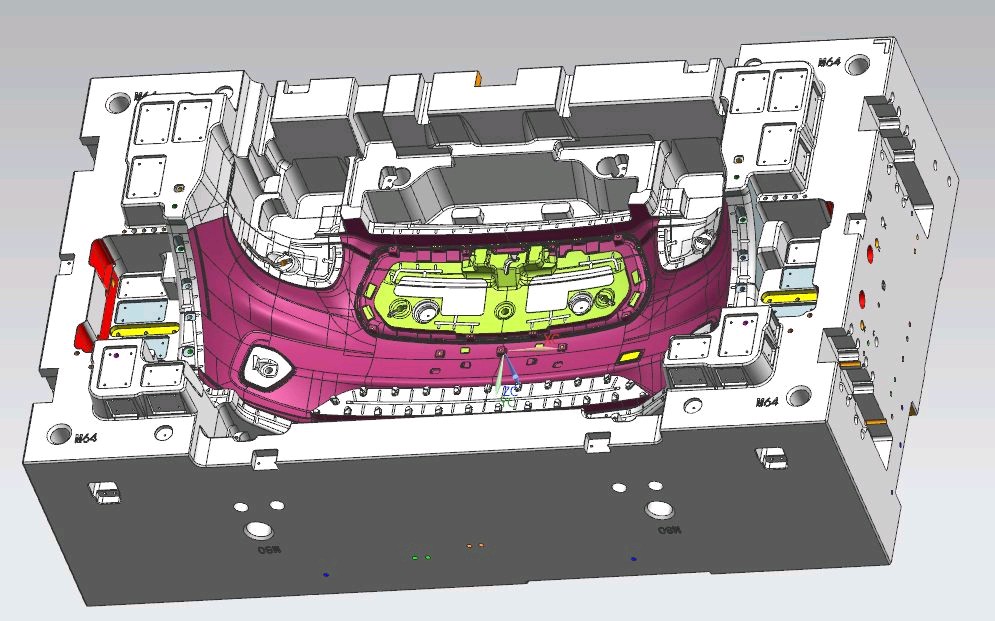

Matters needing attention when processing automobile molds

Automobile molds is a product we see every day, which is used in various interior and exterior decorations of automobiles, such as plastic bumpers, shock absorbers, instrument panels, etc. Therefore, we cannot let go of any detail during processing. Automobile injection molds have much higher req...Read more -

Injection mold manufacturing cycle

Different mold manufacturers, the time it takes to manufacture a pair of injection molds under the premise of the same quality is different. Some people think that the longer the cycle, the finer the workmanship and the better the qual...Read more