News

-

Plastic injection production industry VS plastic raw material development

Injection molding is widely used to make all kinds of plastic parts from the smallest to the largest objects. Generally, the parts to be molded must be designed very accurately to support the injection molding process. When parts are improperly designed, they can easily break or bend during the m...Read more -

Plastic product design and development service

Chapmanmaker provide one-stop service, just design and produce depend on customer’s idea and thought. We are a manufacturer located in China and has got the ISO9001:2015 certs, and our engineer has worked 15 years in plastic industrial. Small product and large product will both be avaiable.Read more -

Injection molding VS 3D Printing

Conform to the needs of the times and the development of technology ,3D printing lauch out. Injection molding is cheaper than 3D printing if you produce more than 100 parts. While the cost per unit using 3D printing stays relatively unchanged, the price for injection molding becomes dramatically...Read more -

The relationship between plastic products and molds

When creating a product that requires molded plastic parts, depending on the type of application and type of part you want to produce, you have several processes to choose from. One of the most popular processes to achieve high quality and cost effective plastic parts is...Read more -

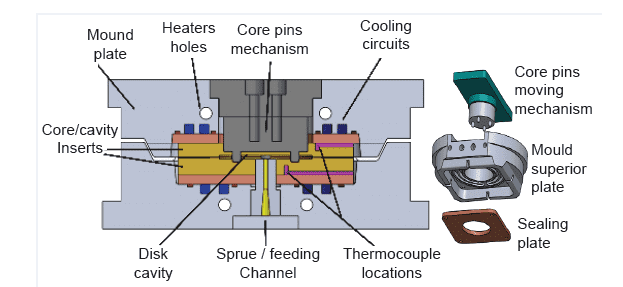

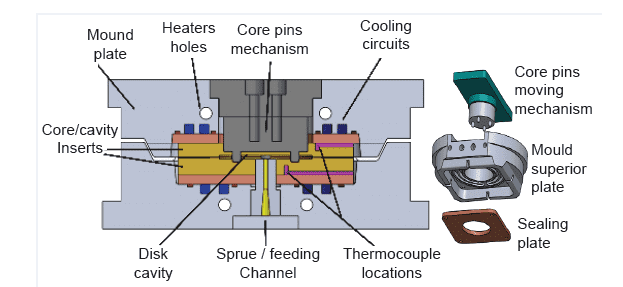

The importance of plastic mold inserts and inserts

Mold core is an extended or male portion of the mould which creates the internal plastic part surface whereas cavity is a depression or female portion of the mould which creates the external plastic part surface.Mold core is a pre-prepared shape of the mould. It is used to provide internal caviti...Read more -

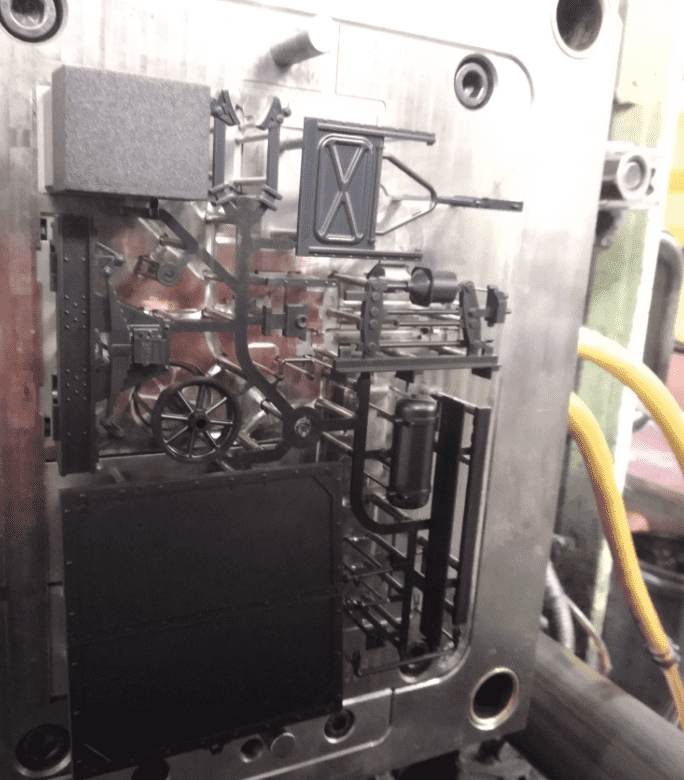

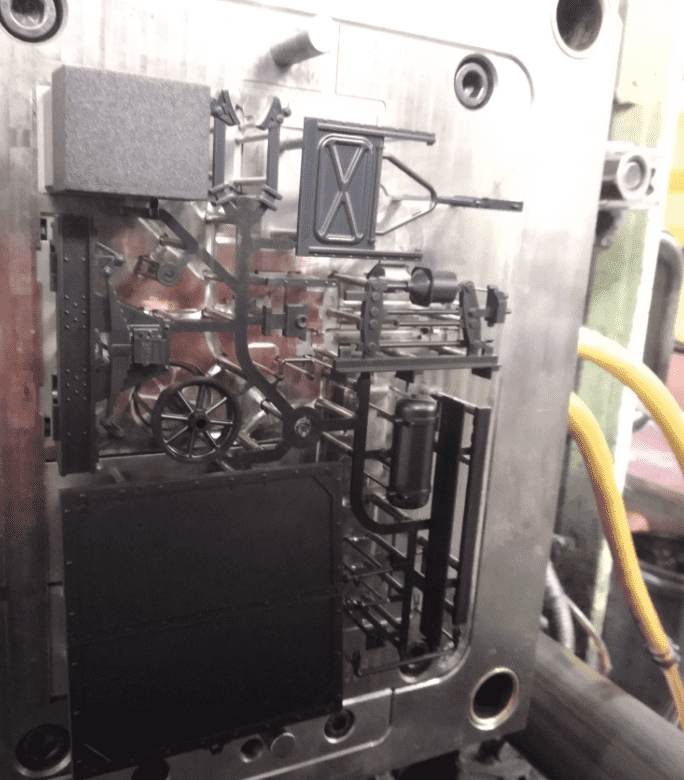

How to make multi-cavity plastic molds?

The use of one mold and multiple cavities for plastic injection molding is becoming more and more common. The most important factor to consider in the design of this type of mold is the filling balance. In the multi-cavity injection molding mold, the runner system is usually designed as an “...Read more -

Product Innovations in the Face of COVID-19

COVID-19 While terrible, times of crisis over the years have also spurred some of history’s most notable inventions still in use today. From the ambulance created during the Middle Ages to help medics get to and transport patients quickly, to duct tape during WWII helping soldiers repair equipmen...Read more -

Mold makers focus on recruiting the next generation

Like more and more other industry trade associations, the China Mold Manufacturers Association has also launched projects aimed at attracting the younger generation. Today, recruiting the next generation of employees has become a top priority for Chinese manufacturers. I know this sounds ...Read more -

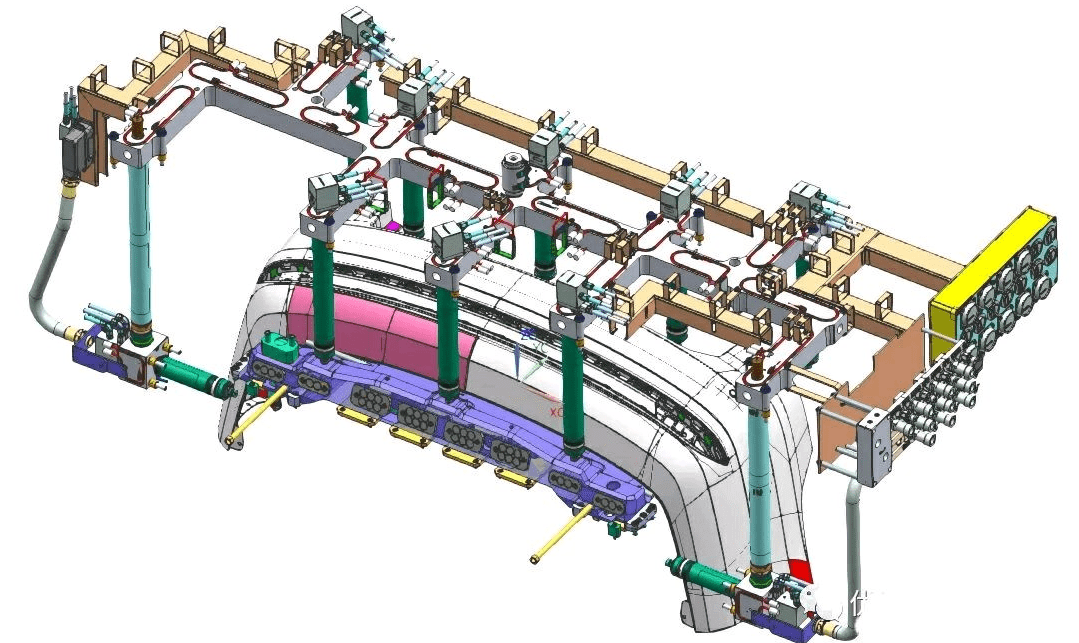

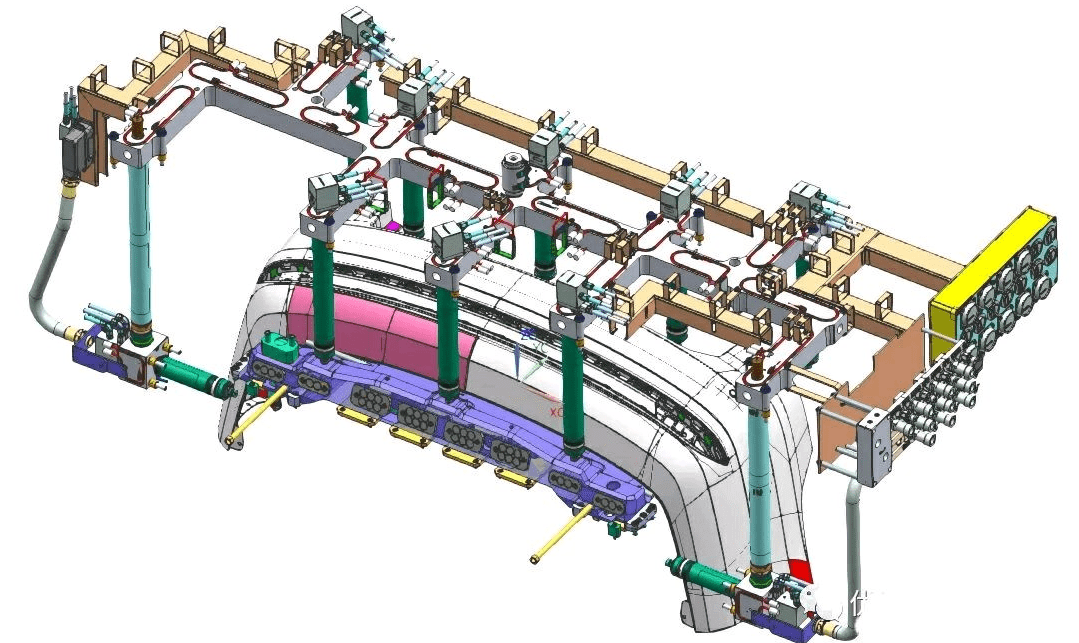

LSR liquid silicone mold application

Liquid silica gel is abbreviated as LSR, which is a product that can be favored by consumers and manufacturers. Liquid silica gel is made of silica gel products. It has good elasticity, waterproof and moisture resistance, and is resistant to acid, alkali and other chemical substances. Generally u...Read more -

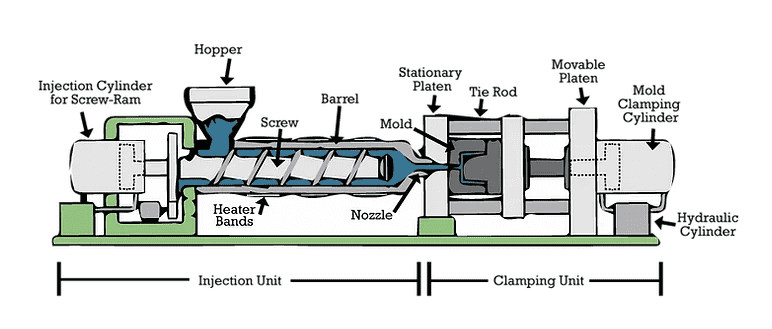

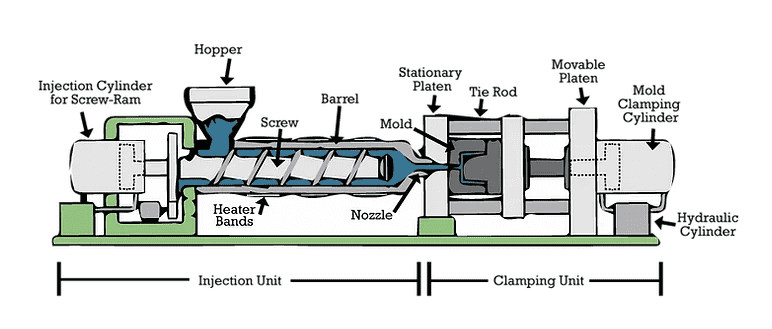

Plastic Injection Molding

Learning the plastic injection molding process can be a little overwhelming at first. Your company has been through weeks, months or maybe even years of research and development to design the newest, most innovative and successful product. You start digging deeper and planning how your product wi...Read more -

Are You Selecting the Proper Material For Your Plastic Components?

Choosing the proper material for any type of product is important to maximize the functionality and profitability of the product. Don’t just consider what the end function of you product is. Make sure you know the ins and outs of how the component will be used and what it will come in contact wit...Read more -

Green Deals: 4-pack Outdoor Solar LED Lights $38 (Reg. $75), more

SolarTech-LED via Amazon offers a four-pack of Outdoor Solar LED Lights for $37.99 shipped when promo code VCTF2UDM is applied during checkout. As a comparison, it typically sells for $75 or so. This is the lowest price that we’ve tracked all-time by nearly $30. Simplify your outdoor lighting set...Read more