Mold Manufacturing - Manufacturers, Suppliers, Factory from China

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Mold Manufacturing, Rapid 3d Printing Service, Plastic Products, Injection Moulding Tool Design,Automatic Work Cells And Robotics. We've been prepared to cooperate with company friends from at your home and overseas and produce a wonderful future with each other. The product will supply to all over the world, such as Europe, America, Australia,Tunisia, Bolivia,Leicester, Rio de Janeiro.We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

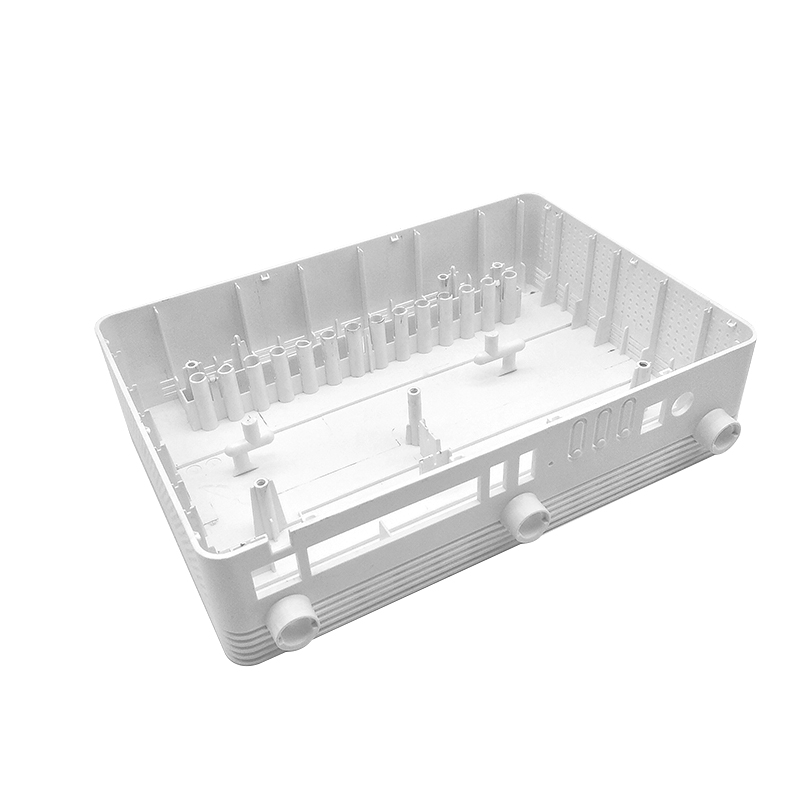

Related Products