Mould - China Manufacturers, Suppliers, Factory

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Mould, Silicon Parts, Prototype Injection Molding, Silicone Mold Manufacturer,Rapid Prototype Abs. The principle of our organization is usually to provide high-quality items, qualified services, and trustworthy communication. Welcome all friends to place trial order for developing a long-term small business relationship. The product will supply to all over the world, such as Europe, America, Australia,United Arab emirates, Bahrain,Riyadh, Rome.Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Make sure you your inquiry for more details or request for dealership in selected regions.

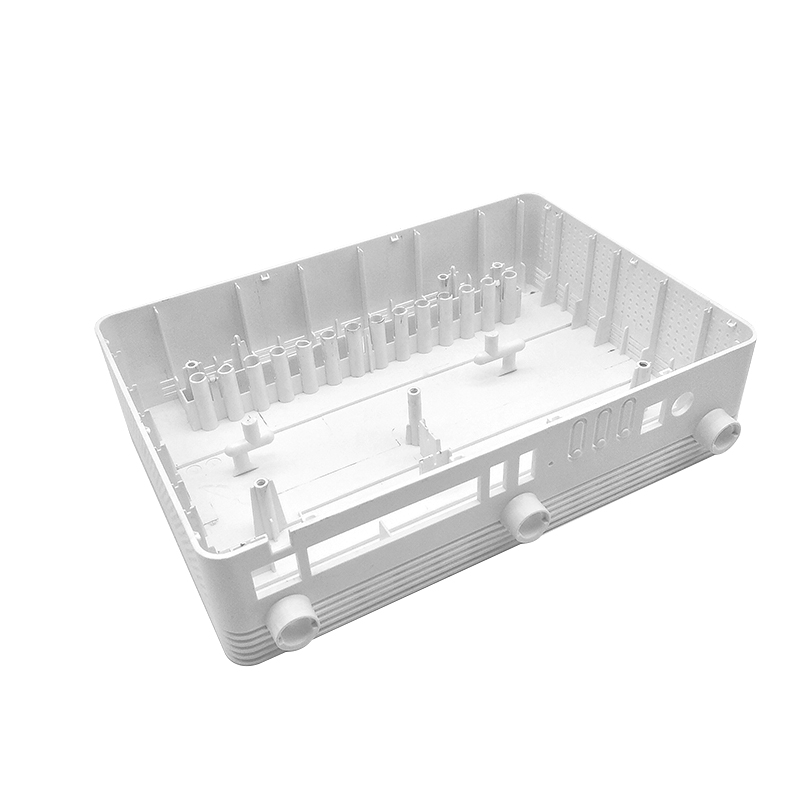

Related Products