Electronic Product - China Factory, Suppliers, Manufacturers

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Electronic Product, Injection Mold Tooling Cost Estimator, Prototype Plastic Molding, Prototype Plastic,Prototype Machine. We aim at Ongoing system innovation, management innovation, elite innovation and market innovation, give full play to the overall advantages, and constantly improve service quality. The product will supply to all over the world, such as Europe, America, Australia,America, Rwanda,Norwegian, Turin.Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

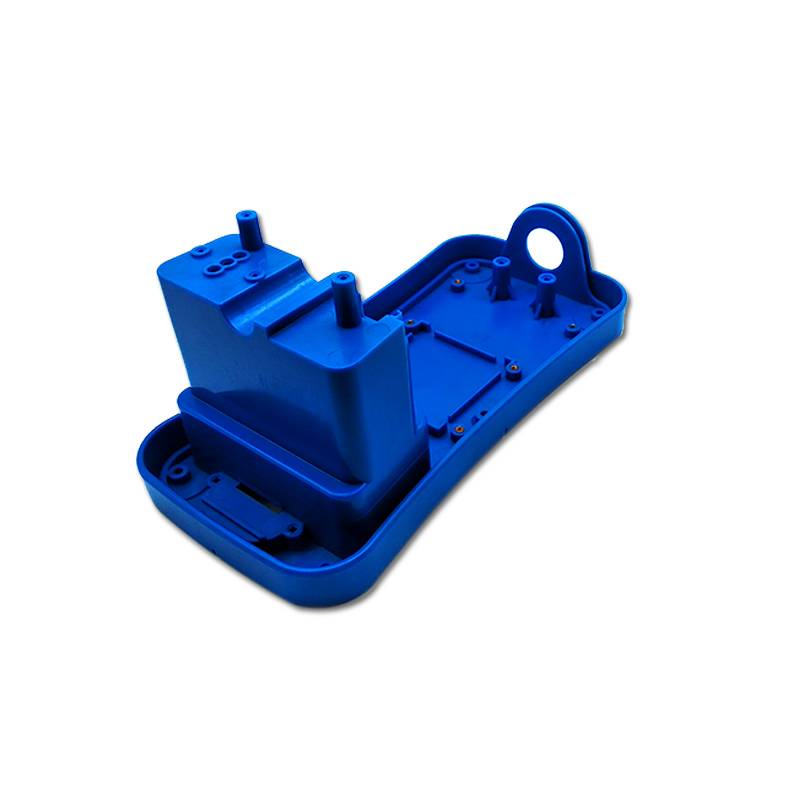

Related Products