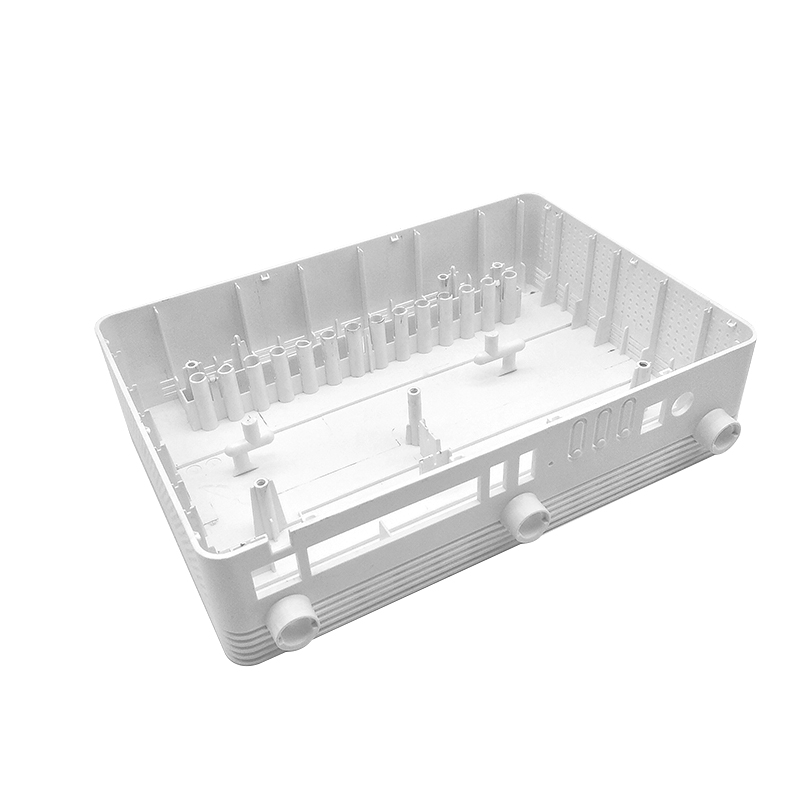

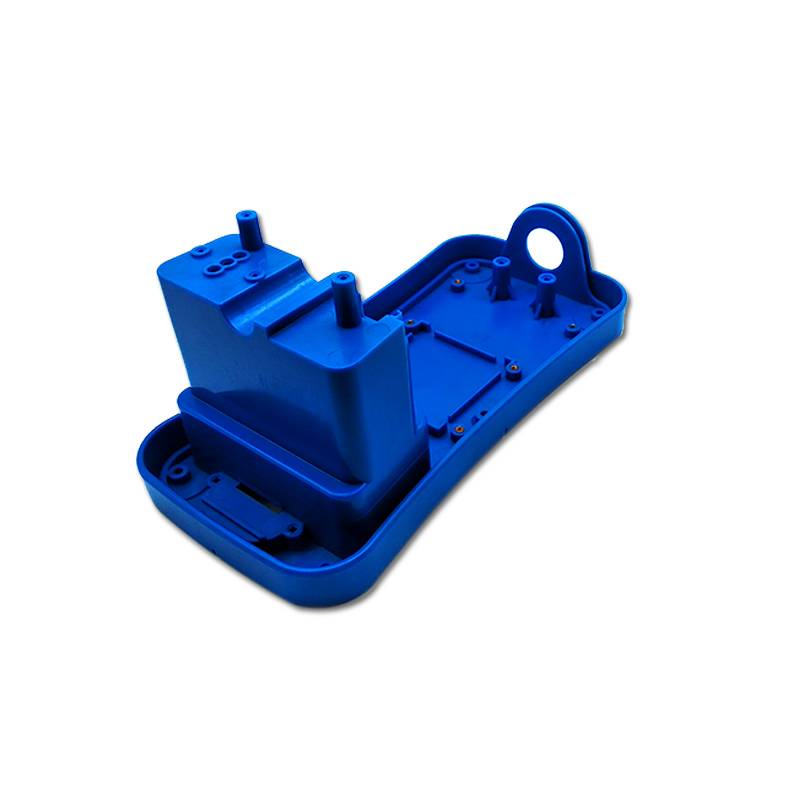

Mold Parts - China Manufacturers, Factory, Suppliers

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for Mold Parts, Family Molding, Automobile Parts, Tool And Die Mold Maker,Injection Molding Tooling Cost. Our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price. The product will supply to all over the world, such as Europe, America, Australia,Senegal, Danish,Algeria, Florida.We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Related Products