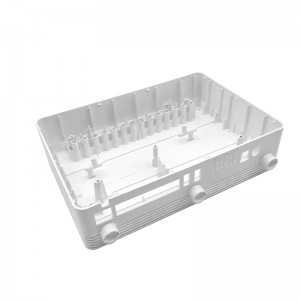

SET-TOP PLASTIC BOX

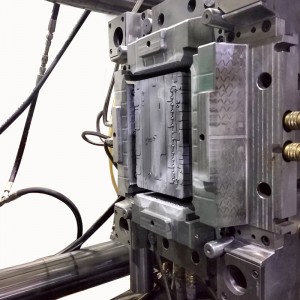

| Mould NO. | CPM22-C2026 |

| Surface Finish Process | VDI-24 |

| Plastic Material | PC+ABS |

| Part weight | 101g |

| Design Software | UG |

| Part size | 220*150*13 mm |

| Customized | Customized |

| Application | Appliances |

| Mould size | 500 * 450 * 461mm |

| Part Name | SET-TOP PLASTIC BOX |

| Mould Cavity | 1*1 |

| Runner | point gate(hot runner system) |

| Standard | LKM |

| Mould Material | S136(HRC48-52) |

| Mould Life Cycle | 500,000 |

| Lead Time | 42 days |

| Mould Cycle Time: | 36's |

| Payment | T T |

Application field::

Set top boxes are the perfect way to give new life to an older TV. Use it for digital TV, record your favourite shows, and even play your stored shows or movies on the USB playback. Easy connection through HDMI, Full 1080 HD, and a time shift function to help you get to the important bits. Chapman Maker has provided mold and injection molding services for a number of set-top box manufacturers, and has been recognized by our customers. Not only the appearance requirements, the service life or the user experience, our appearance quality is the best.

Write your message here and send it to us