The difference between 2k mold and ordinary plastic mold

The definition of the mould is also different, and the mould color material is only divided into two types in the product category on the same mould. Generally speaking, this mould color process is called mould processing process, which is usually composed of mould color process finish.

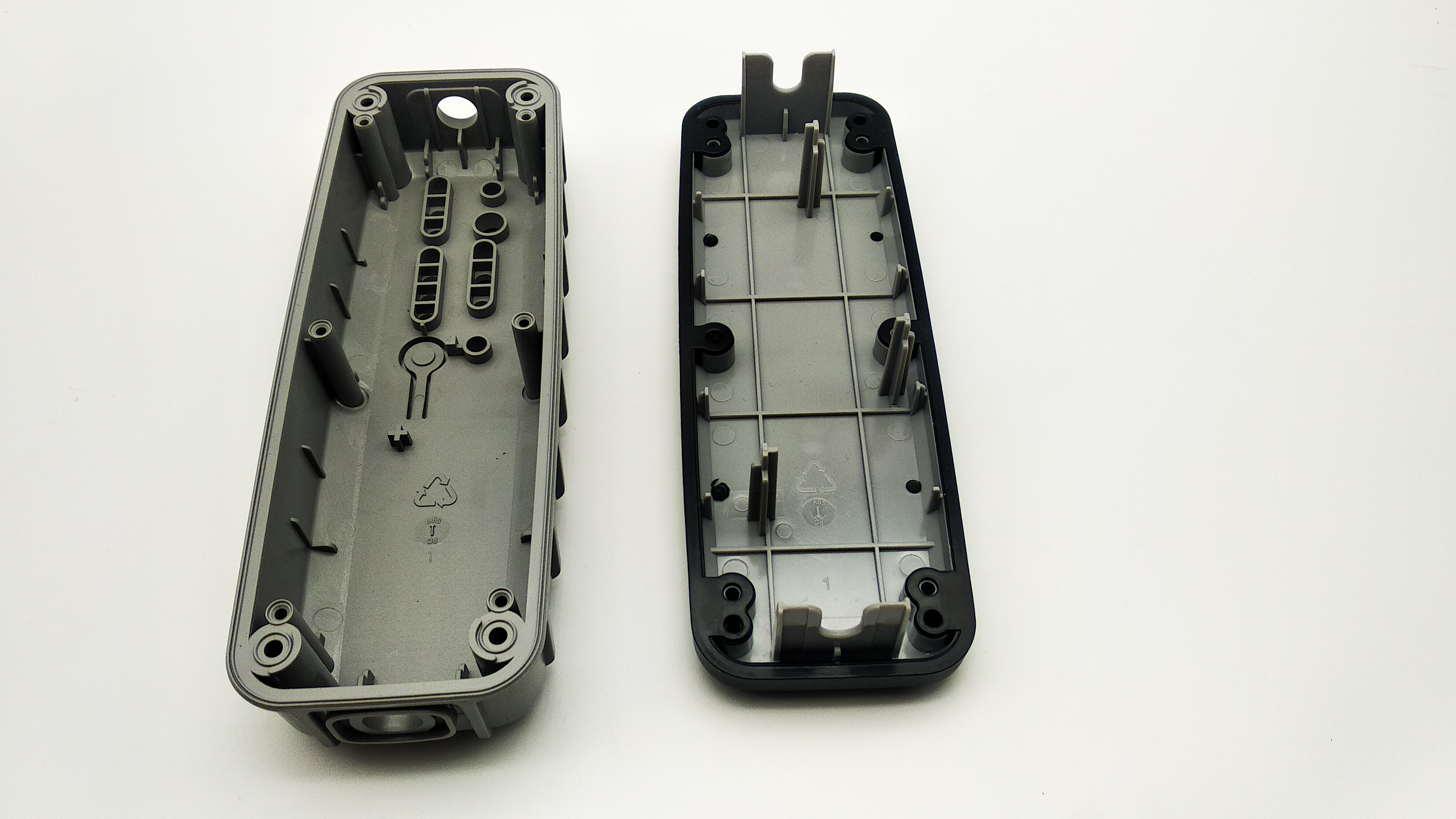

2k moulds may be unfamiliar to everyone, but when it comes to two-color products, they are familiar. Sometimes when we use some electronic products or instruments, you will find that their shells have a characteristic, the colors on the shells are different, And it will not fade for a long time, always maintain the original appearance, the appearance is still as bright and beautiful, and the operation feels very good, and the focus is very environmentally friendly.

2k mould and ordinary plastic moulds Only in this case, ordinary plastic moulds have color systems, which are composed of a different ordinary color system raw materials through two-color combination, while the color system of ordinary plastic moulds is different. The reason for the freshness is that the color of the two-color mould is different and not the reason for the color.

In order to achieve two or more colors of ordinary plastic moulds, it must be completed by spraying secondary processing technology. The paint is easy to fade and is not environmentally friendly, so many companies will choose two-color mould processing to avoid this problem, but the premise is that the two-color mould has one more set of moulds than the ordinary plastic mould, and the cost of moulding is higher. If the product is large in volume, the trial product has a strong competitiveness and a long-term market. Because the cost of ordinary plastic mould products through the secondary processing process of spraying is also very high.

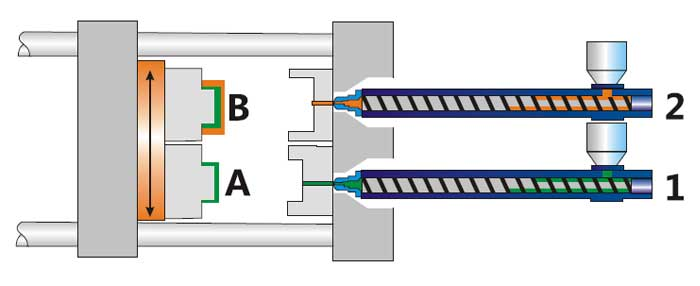

2k moulds are becoming more and more popular in the market, because this process can make the appearance of products more beautiful, easy to change colors without spraying, and high technical requirements. Two-color moulds require two sets of moulds, the front mold is different, the two rear moulds are the same, and the guide post should not be offset, especially in the design, the selection of plastic materials for the two-color mould: semi-finished products A material with a high melting point must be selected, and a material with a low melting point for the finished product must be selected.

Chapman Technology Co., Ltd. specializes in the design, manufacture and injection moulding of plastic moulds (single-color, two-color). The company has a clear division of labor and mature technology.

Welcome to visit our website, if you need help or have any new plastic moulding project to quote, please contact us through the following ways, we are always here to help you online.

Sales Email: info@chapmanmaker.com

Post time: Apr-27-2022