It is also a plastic material. Why can some be called engineering plastics

"Engineering plastics can be used as engineering materials and plastics instead of metals to manufacture machine parts. Engineering plastics have excellent comprehensive properties, high rigidity, low creep, high mechanical strength, good heat resistance and good electrical insulation. They can be used for a long time in harsh chemical and physical environments. They can replace metals as engineering structural materials, but the price is expensive and the output is small.". Let's take a look at the definition of Japanese industry that "it can be used as high-performance plastics for construction and mechanical parts, with heat resistance above 100 ℃, which is mainly used in industry". After careful deliberation, it is not difficult to find that in fact, the written definitions are very broad, and only the standards are given from the application environment and products of materials.

In fact, many materials classified as "general plastics" can also be used to replace steel with plastics and can withstand high temperature. However, from the process of application and development, they do not meet the engineering emphasis that "more human and material resources are needed to carry out large and complex work, which should be completed in a long time cycle". The development cycle of engineering plastics is longer than that of general plastics, with more steps, more complex analysis software and equipment, and greater risk of trial and error. Under normal circumstances, the process of product development and selection of materials can be divided into the following steps:

1、 Define the key requirements of the product, i.e. CTQ, such as V0 flame retardant, long-term service temperature higher than 80 ℃, tensile modulus greater than 10GPa... The requirements should be specific, and it is better to have detailed data definition.

2、 According to CTQ, preliminarily screen the material types, such as nylon 66, glass fiber reinforced PC, POM, etc. at this time, we should not only look at the product manual issued by the material manufacturer, but also look at the application cases of known materials. Referring to the requirements and reasons for selecting materials for similar products of other manufacturers can reduce the trial and error cost of the project in this step and shorten the project development cycle.

3、 Select the specific material specifications according to the material types determined in the previous step. When selecting the specifications, you should not only refer to the application cases of known materials, but also refer to the reference price in the table of known material properties to understand the cost and procurement channels of raw materials in advance.

4、 After selecting the specific material specifications, the feasibility analysis needs to be carried out before opening the mold. Carry out mold flow analysis and optimize mold design for more complex structural parts, and even some products need more verification of 3D printed models.

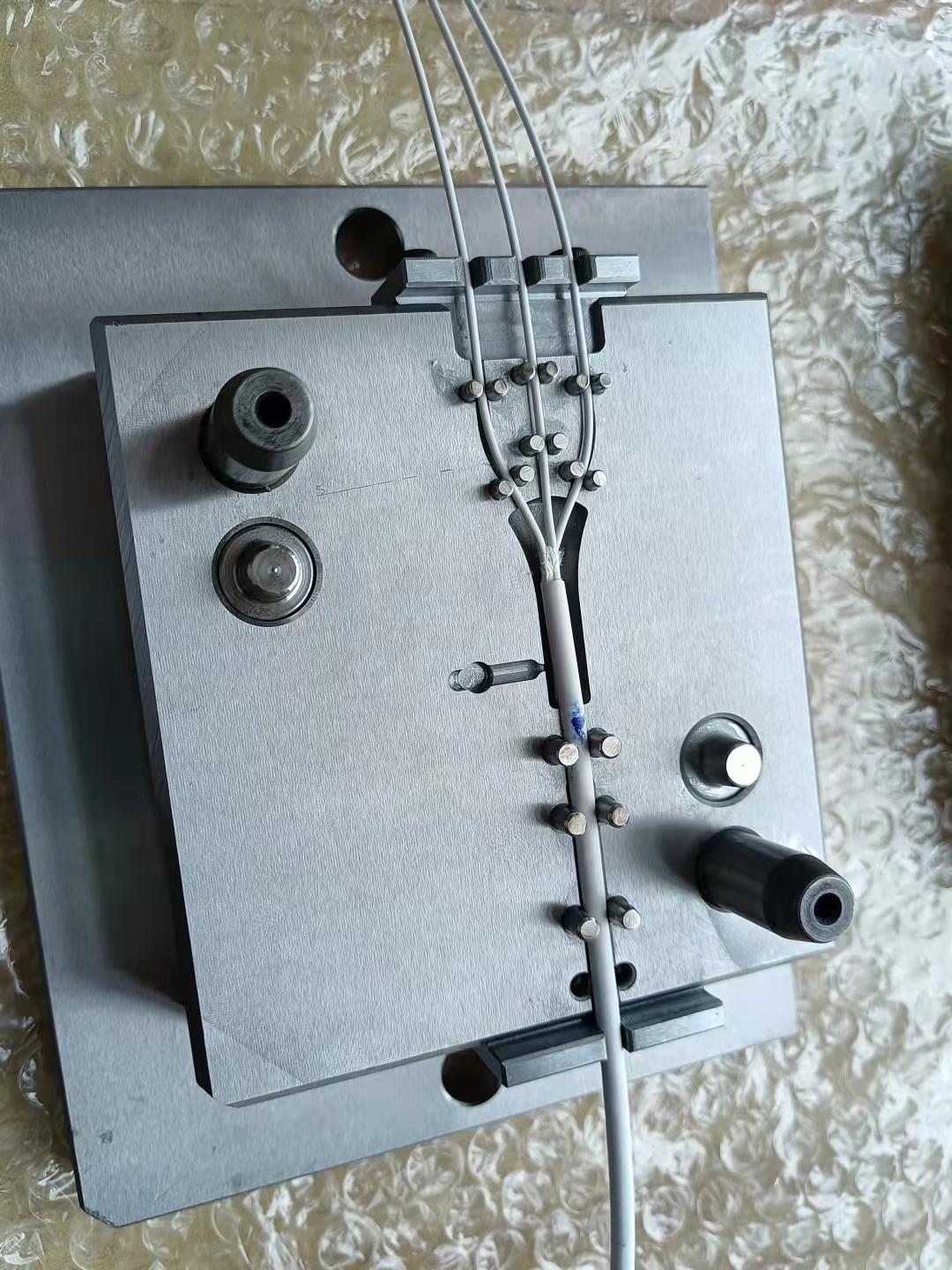

5、 After all kinds of verification, the mold can be opened. After the mold is completed, the mold can be tested to verify whether the mold can work normally, and the performance of product samples can be tested. This process is also a high incidence stage of errors, and most of them need to be optimized, adjusted and re optimized in many rounds over and over again. Discuss with senior engineers about the material and molding process.

This is a typical application and development process of engineering plastics, which is in line with the engineering process and methodology. Of course, this is only the definition of engineering plastics from the perspective of application development. Polymerization and modification are also another perspective from which engineering plastics are different from general plastics.

If you have any new enquiry of the plastic molding, R&D. Please kindly feel freely contact Chapman Maker Team. They will give you very professional guidance and the most competitive price.

Email: info@chapmanmaker.com

Post time: Mar-23-2022