Professional Design China Quick Communication Fast Delivery OEM Supplier of Injection Plastic Parts

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Professional Design China Quick Communication Fast Delivery OEM Supplier of Injection Plastic Parts, We welcome new and outdated consumers from all walks of life to make contact with us for long run small business relationships and mutual success!

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for factory, Plastic parts supplier, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We’ve been specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry might be replied as soon as possible.

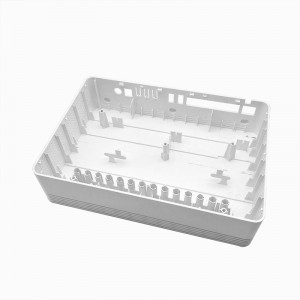

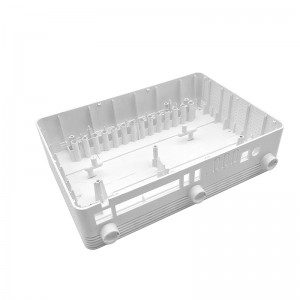

| Mould NO. | CPM-191001 |

| Surface Finish Process | MT-11010 |

| Plastic Material | PA66 |

| Part weight | 71.7g |

| Design Software | UG |

| Part size | 145mm X 72mm X 21mm |

| Customized | Customized |

| Application | Automobile |

| Mould size | 350 X 400 X 381mm |

| Mould Name | Car Parts Muold |

| Mould Cavity | 1*2 |

| Runner | One INCOE Hot runner change cold runner for sub gate |

| Standard | Hasco |

| Mould Material | 1.2343/1.1730/1.2767 |

| Mould Life Cycle | 500,000 |

| Lead Time | 35days |

| Mould Cycle Time: | 32′s |

| Payment | T T |

Application field

Vehicle doors often include brakes, or ‘stays’, that slow the door down just before it closes, and also prevent the door opening further than its design specification. The current trend is to have a three-stage door brake.

Door brakes exist because the doors on the first vehicles were heavy, so they had to be pushed hard to make them close. Soon after, automotive manufacturers managed to construct lighter doors, but users were used to closing doors with force so doors quickly became damaged. Door brakes were then introduced to slow down the door just before the door closed to prevent damage; these soon became standard.

A conventional door, also known as a regular door is hinged at the front-facing edge of the door, and so allows the door to swing outward from the body of the car. These doors are relatively safe, in that if they are opened during forward motion of the vehicle, the wind resistance will work against the opening door, and will effectively force its closure. The operation of a vehicle door entering, exiting, or standing out side an opened vehicle door is extremely dangerous particularly at night even when looking both ways. The issue is the vehicle door in most cases provides not visual warning to other vehicle drivers to allow accident avoidance of another vehicle driver to have the time to take avoidance measures. New advancements have been made to allow the viewing of the opened vehicle door at night with the addition of highly reflective tape applied to the lower interior edge of the vehicle door . These new advancements allow the opened vehicle door to be seen even with a person blocking the prior art systems such as a reflector or a light by providing reflex reflectivity exceeding fifty percent of the vehicle door behind a person legs blocking the opened vehicle door at night.

Project Management

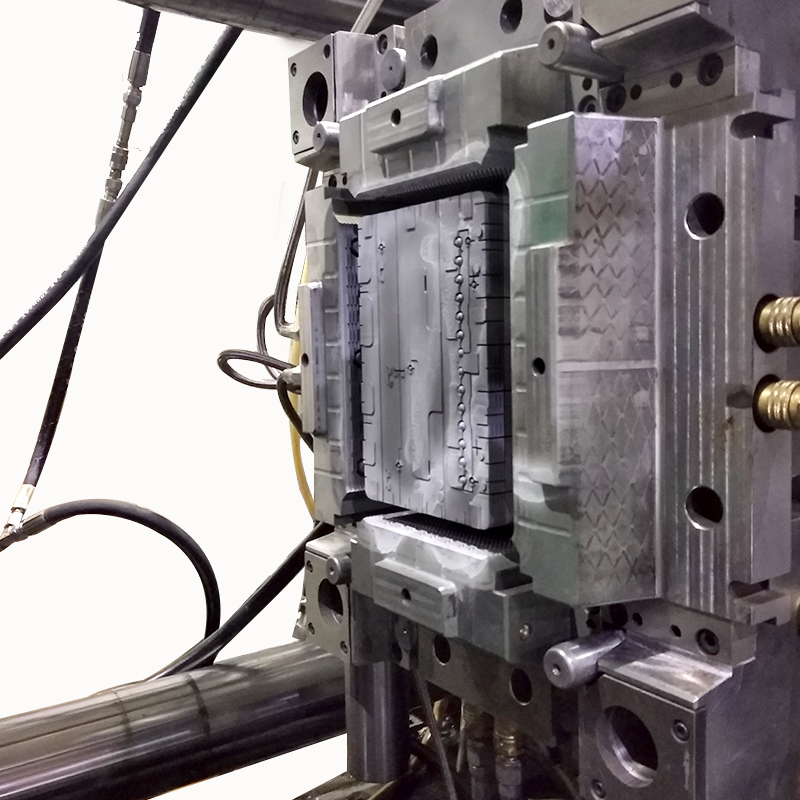

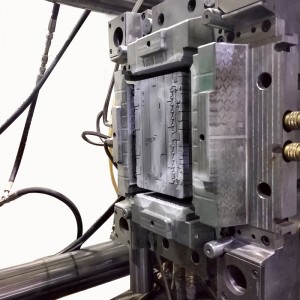

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Professional Design China Quick Communication Fast Delivery OEM Supplier of Injection Plastic Parts, We welcome new and outdated consumers from all walks of life to make contact with us for long business relationships and mutual success!

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Professional Design China Quick Communication Fast Delivery OEM Supplier of Injection Plastic Parts, We welcome new and outdated consumers from all walks of life to make contact with us for long business relationships and mutual success!

Professional China Injection plastic Parts, Plastic Parts Moulding, We’ve been specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry might be replied as soon as possible.