OEM Supply Insert Injection Molding Process - Big discounting China Custom Injection Plastic Molded Parts for Automotive Parts – Chapman

OEM Supply Insert Injection Molding Process - Big discounting China Custom Injection Plastic Molded Parts for Automotive Parts – Chapman Detail:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Big discounting China Custom Injection Plastic Molded Parts for Automotive Parts, Items won certifications while using the regional and international primary authorities. For far extra detailed info, please contact us!

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for China Injection Molding, Plastic Injection Mould, With many years good service and development, we’ve a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

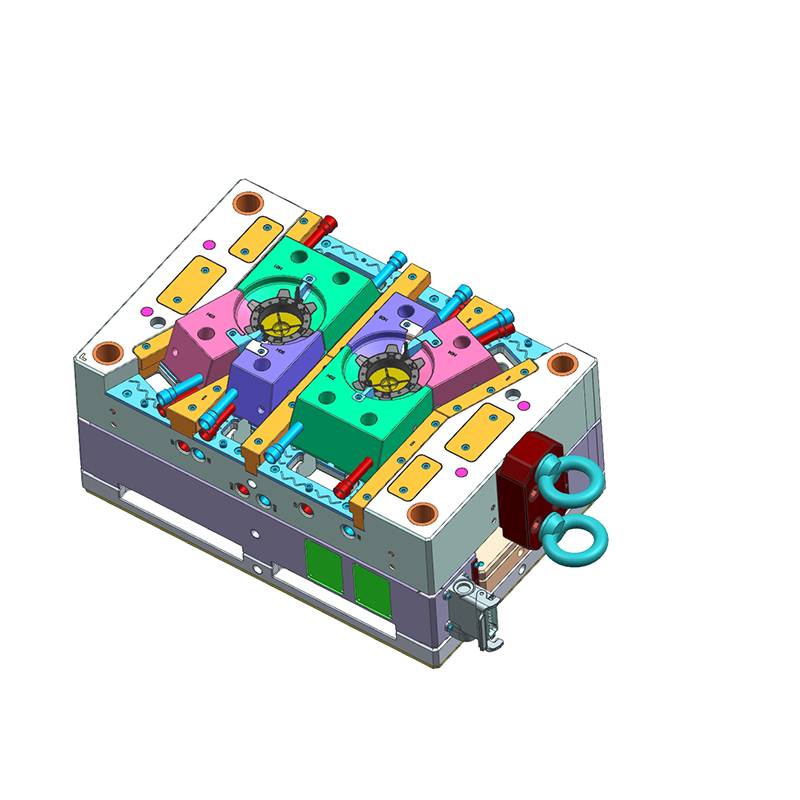

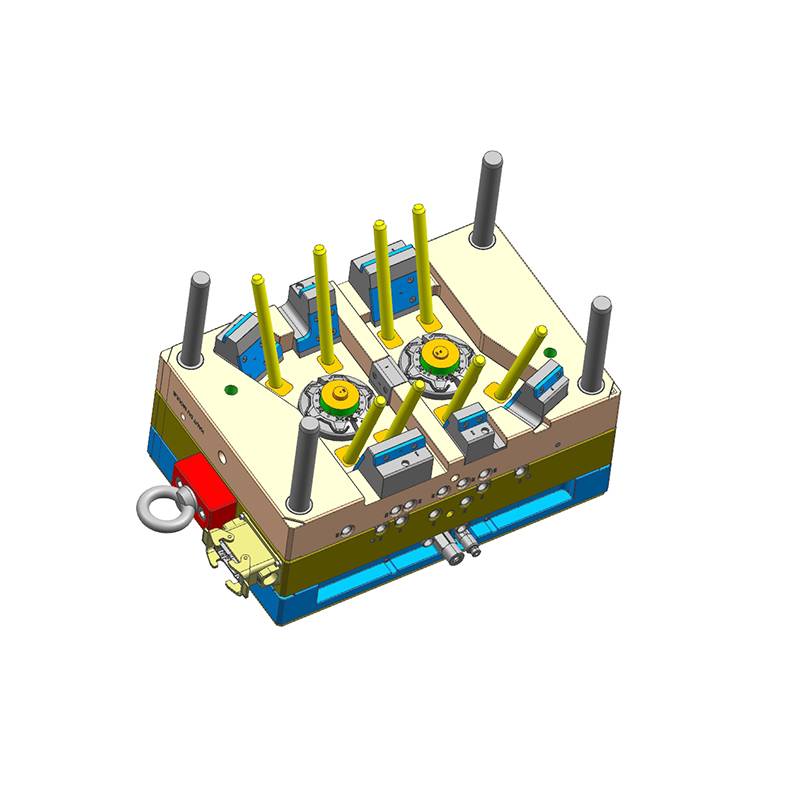

| Mould NO. | CPM-150216 |

| Surface Finish Process | VDI-21 |

| Plastic Material | PA4.6 |

| Part weight | 1.2g |

| Design Software | UG |

| Part size | 103.58*103.58*60.62 mm |

| Customized | Customized |

| Application | Automobile |

| Mould size | 396 * 596 * 531mm |

| Mould Name | Insulating Bobbin |

| Mould Cavity | 1*2 |

| Runner | Hot runner for point gate |

| Standard | Hasco |

| Mould Material | 1.2343ESU/1.2312/1.2767 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 45 days |

| Mould Cycle Time: | 12′s |

| Payment | T T |

Project Management

We have 12 Design Engineers with an average of 10 years design experience and a technical college level of education. The team will discuss every new project together and find the perfect solution for it, based on our knowledge and successful experience. We use 3D software to design the mold and Moldflow to verify and optimize the design, so that we can ensure it’s success.

After receiving your PO and part print, we will discuss and recommend any changes we think are necessary to make the part mouldable. We will then provide you with a DFM design report within two days to one week for you to review. We will discuss and then submit the part demoulding method and finalized mould design for your approval, before purchasing and cutting the steel. This process guarantees that we fulfill all of your design requirements.

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Big discounting China Custom Injection Plastic Molded Parts for Automotive Parts, Items won certifications while using the regional and international primary authorities. For far extra detailed info, please contact us!

Big discounting China Injection Molding, Plastic Injection Mould, With many years good service and development, we’ve a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for OEM Supply Insert Injection Molding Process - Big discounting China Custom Injection Plastic Molded Parts for Automotive Parts – Chapman , The product will supply to all over the world, such as: Munich, Bangalore, Anguilla, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.