Mold temperature is the most important variable in injection molding—no matter what kind of plastic, it must be ensured that the mold surface is substantially wet. A hot mold surface keeps the plastic surface liquid long enough to build pressure within the cavity.

Reproduction of the cavity surface is high if the cavity is filled and the cavity pressure can press the soft plastic against the metal before the frozen skin hardens. On the other hand, if the plastic entering the cavity at low pressure is suspended, no matter how short, its slight contact with the metal can cause smearing, sometimes referred to as gate smearing.

Higher mold temperature means less flow negative force. On many injection molding machines, this naturally means that faster results in higher effective pressures in the sprue and cavity. May be flashed. Since the hotter model does not freeze the plastic that entered the flash area before the high pressure builds up, the furnace charge flashes around the ejector pin and overflows into the parting line gap. This shows the need for good injection rate control, which some modern flow control programmers do.

In general, an increase in mold temperature reduces the condensation layer of the plastic in the cavity, allowing the molten material to flow more easily in the cavity, resulting in greater part weight and better surface quality. At the same time, the increase in mold temperature will also increase the tensile strength of the part.

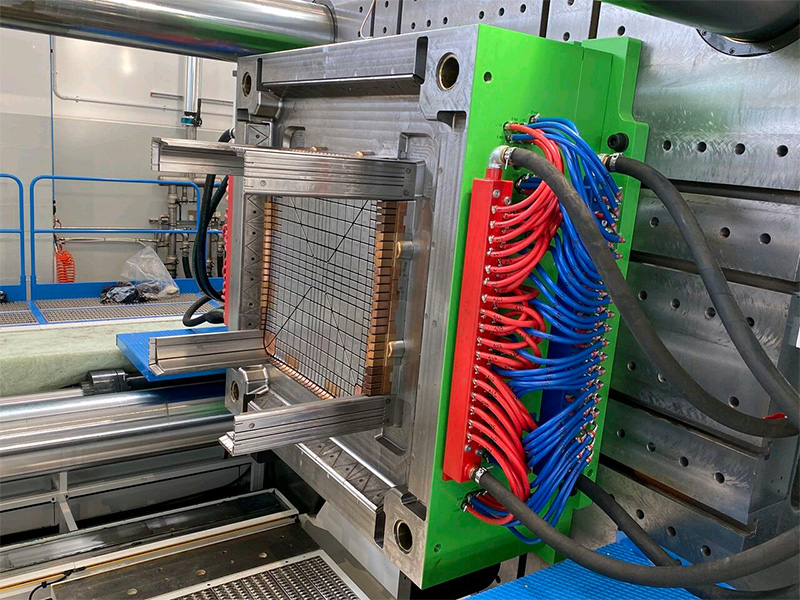

Mold insulation method

Many molds, especially engineering thermoplastics, operate at relatively high temperatures, such as 80 degrees Celsius or 176 degrees Fahrenheit. If the mold is not insulated, the heat lost to the air and the injection molding machine can easily be as much as the shot cylinder.

Therefore, insulate the injection mold from the machine plate, and if possible, insulate the surface of the mold. If considering a hot runner mold, try to reduce the heat exchange between the hot runner part and the cooled injection part. Such an approach can reduce the warm-up time for energy loss.

Welcome to visit our website, if you need help or have any new plastic molding project to quote, please contact us through the following ways, we are always here to help you online.

Email: info@chapmanmaker.com

Post time: Apr-23-2022