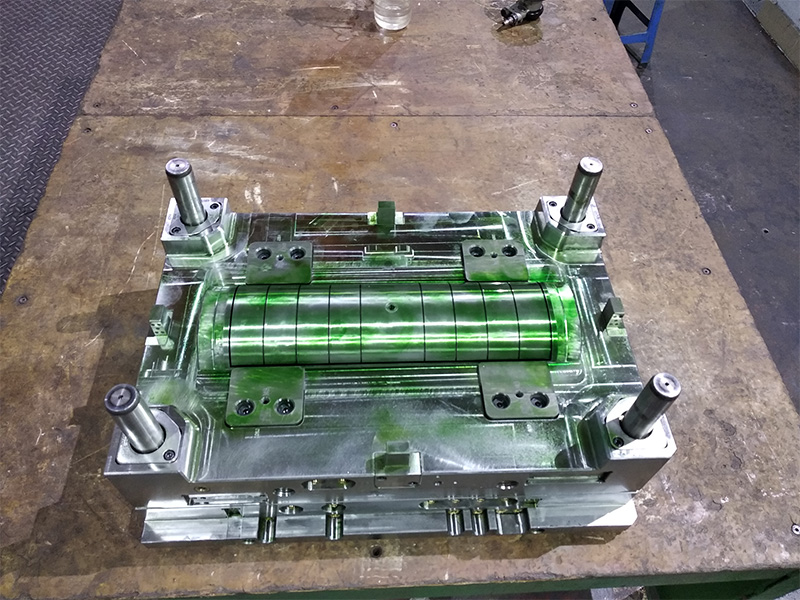

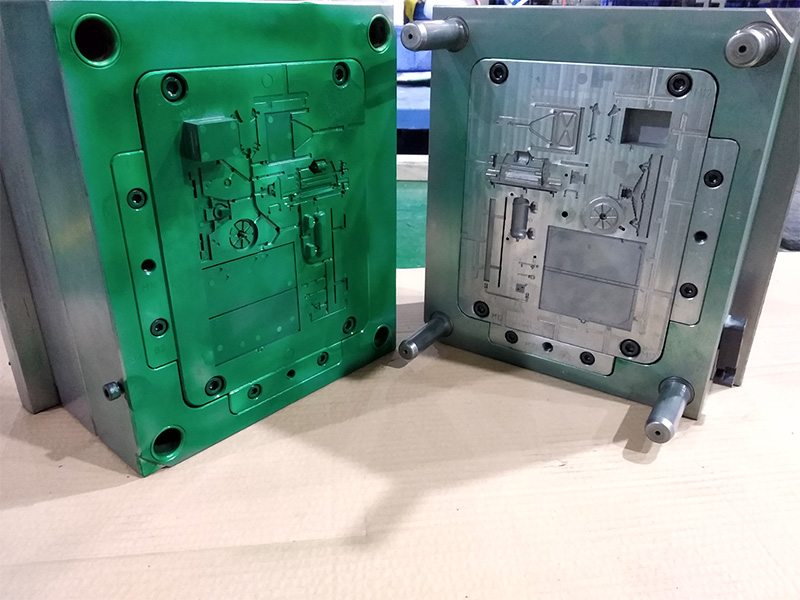

Injection mold is a tool for producing plastic products, and it is also a tool for giving plastic products complete structure and precise dimensions. Injection molding is a kind of processing method used in mass production of some complex-shaped parts. Specifically, it refers to the injection of heated and melted plastic into the mold cavity by high pressure from an injection molding machine, and after cooling and solidification, a molded product is obtained.

Scope of application: injection molds are suitable for thermoplastics such as ABS, PP, PC, POM, etc., while thermosetting plastics such as phenolic plastics, epoxy plastics, etc. use rubber molds;

Injection mold classification: by structure: two-plate mold, three-plate mold; by nozzle: large nozzle, point nozzle, hot water nozzle.

The Chapman maker team made a clear point that in the daily production operation, the maintenance of the mold is more important than the maintenance of the mold, because the maintenance of the mold and the mechanical equipment is the same reason, the more times the mold is repaired, the better the performance of the mold will be. To a certain extent, the usage time of the mold is reduced, but if we maintain the mold regularly, the usage time of the mold will be extended accordingly. Therefore, we must do a good job in mold maintenance.

※ The importance of mold maintenance:

Maintain the normal operation of the mold and reduce unnecessary wear of the moving parts;

Make the mold reach the normal service life;

Reduce oil pollution in production.

※ Mold maintenance classification:

Daily maintenance of molds;

Regular maintenance of molds;

Maintenance of the appearance of the mold.

Contents of mold maintenance

※ Daily maintenance:

Refueling of various moving parts such as thimble, row position, guide post and guide sleeve;

Cleaning of the die surface;

channel for transporting water;

※ Regular maintenance:

Refueling of various moving parts such as thimble, row position, guide post and guide sleeve;

Cleaning of the die surface;

channel for transporting water

Clean the exhaust slot, add exhaust to the trapped gas burning black level;

Repair of damaged and worn parts;

※ Mold maintenance precautions

Sports parts, daily maintenance must be refueled;

The die surface must be clean: label paper should not be pasted on the P/L surface, and the product will continue to be delivered without removing the die before the product is glued, and the glue at the P/L position is serious;

If abnormality is found, such as abnormal ejection, loud noise of opening and closing molds, etc., it must be repaired in time.

※ Safety issues in mold repair and maintenance

Safety issues must be given top priority. Mold repair and maintenance are dealing with molds and equipment (steel). This issue must be paid great attention to.

When using the lifting ring, it must be checked first to ensure that it is intact;

When using equipment, especially when flying debris is generated, be sure to wear glasses to operate;

Wear protective clothing and protective glasses when welding;

It is strictly forbidden to work on the bottom of the mold;

When the machine is operating, it is necessary to ensure that the injection molding machine is in a stopped state and hang the sign.

In Chapman, our technicians will regularly maintain the customer's mold. During the use and operation of the mold, we must follow the normal operation and check the mold in time. When the mold is found to be damaged or worn. , to carry out maintenance in time to prolong the service life of the mold, it must be carried out in accordance with the principle of maintenance first and repair later.

Got a question about plastic mold maintenance, Contact us.

Email: info@chapmanmaker.com

Post time: Apr-19-2022