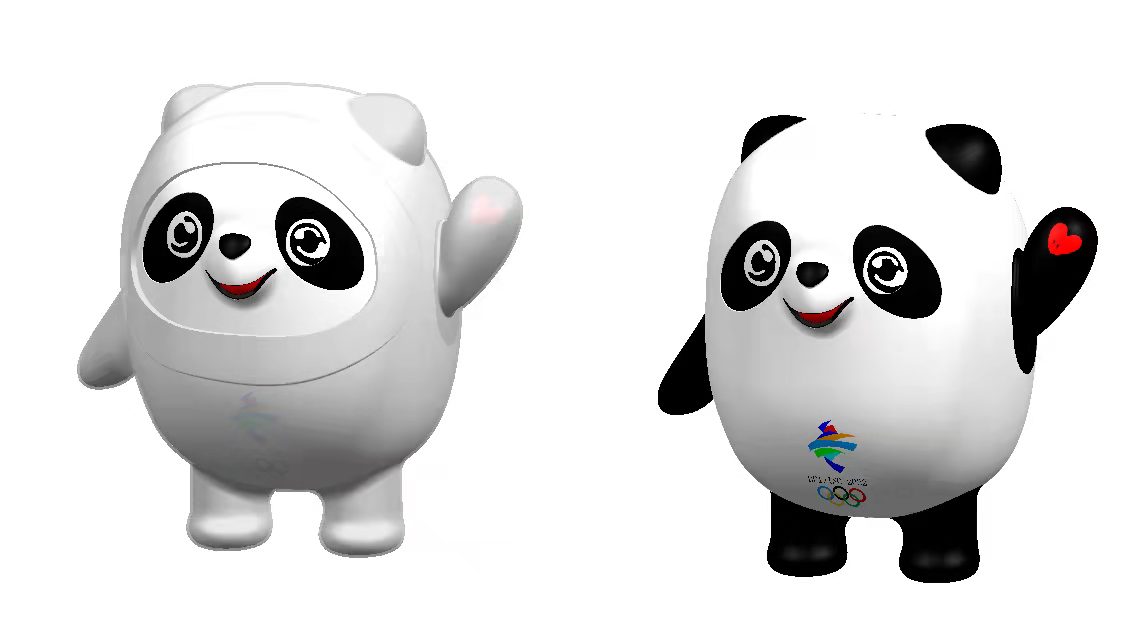

Bing Dwen Dwen, the Winter Olympic mascot, has completely come out of the sky with the successful Winter Olympic Games in Beijing.

Lin Cunzhen, a senior expert of the cultural activities department of the Beijing Winter Olympic Organizing Committee, once said " Bing Dwen Dwen is a common panda. It is only because of this shell that it becomes an ice pier.."

The popular Bing Dwen Dwen is made up of two parts: silicone shell and plush panda.

In the toy industry, the process of producing plush pandas is not difficult; The more difficult part is on the silicone shell.

Bing Dwen Dwen has a high transparency on the silicone shell, and this material has good handle and can reach the level of environmental protection food. The liquid silicone rubber injection molding machine is used for its production. The mold temperature machine needs to be used to accurately heat and cool the mold to ensure the molding of silicone rubber shell.

With the more and more extensive application of liquid silica gel products, there are more and more applications in various industries such as electronics, seals, automobiles, medical treatment, baby products, diving, kitchen and adult products. According to statistics, in the European and American markets, 80% of silica gel products have adopted advanced liquid silica gel injection molding process, and less than 20% of low-end products adopt solid process, In the Chinese market, only 20% use liquid injection molding process. From the perspective of application and future development, liquid injection molding process will be applied more and more. In addition to machinery, materials and personnel, the most important thing for liquid silica gel products is liquid silica gel mold.

What are the technical difficulties of liquid silica gel mold?

1. Liquid silica gel is a material with particularly good fluidity, and the gap higher than 0.002 will run into the glue. Therefore, the requirement for precision is very high, which requires high-precision processing equipment and high-precision mold testing equipment, which is the most basic requirement.

2. Secondly, the temperature control should be very accurate. In the mold design, the design of heating system and heat transfer channel is very important. Different heating elements should be selected according to different materials and structures, such as heating pipe heating, oil temperature heating or high-pressure steam heating, For the conduction of temperature in different metal media, how to control the temperature difference is a technical difficulty.

3. The design and processing control of flow channel, according to the different requirements of product requirements and efficiency, design different flow channel modes, cold flow channel (open, needle valve type), semi cold flow channel, ordinary flow channel and so on

4. The treatment method of exhaust gas can be selected according to the actual situation, such as opening ventilation slots or vacuumizing.

5. With the cooperation of automatic chemical equipment, in order to achieve high efficiency in the production of silica gel products, we must consider the problem of demoulding, whether it is air stripping, automatic manipulator clamping, ejection or blowing, which should be specially considered in the design and manufacture of molds.

You can consult Chapman maker for any link of the solution document of liquid silica gel injection molding, and get involved in the development of liquid silica gel injection molding process. You have a full set of solutions from machinery, mold, tooling, personnel training and so on. Now call Mr. PI at + 86-0755-28269320, or visit the website at "www.chapmanmaker.com" can get professional guidance.

Have questions about liquid silicone mold or liquid silicone rubber injection molding machine? Contact us and one of our project managers will contact you.

E-mail: info@chapmanmaker.com

Post time: Feb-19-2022