Fixed Competitive Price China High Precision Molding Inject Plastic Injection Molding Mold Customized Nylon Plastic Part

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Fixed Competitive Price China High Precision Molding Inject Plastic Injection Molding Mold Customized Nylon Plastic Part, We sincerely expect exchange and cooperation with you. Let us move forward hand in hand and achieve win-win situation.

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for China Customized Nylon Plastic Part, High Precision Molding, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

| Mould NO. | CPM-150226 |

| Surface Finish Process | VDI-24 |

| Plastic Material | PA66+30GF |

| Part weight | 18.65g |

| Design Software | UG |

| Part size | 45.00*25.0*18.0 mm |

| Customized | Customized |

| Application | Connectors |

| Mould size | 250 * 250 * 311mm |

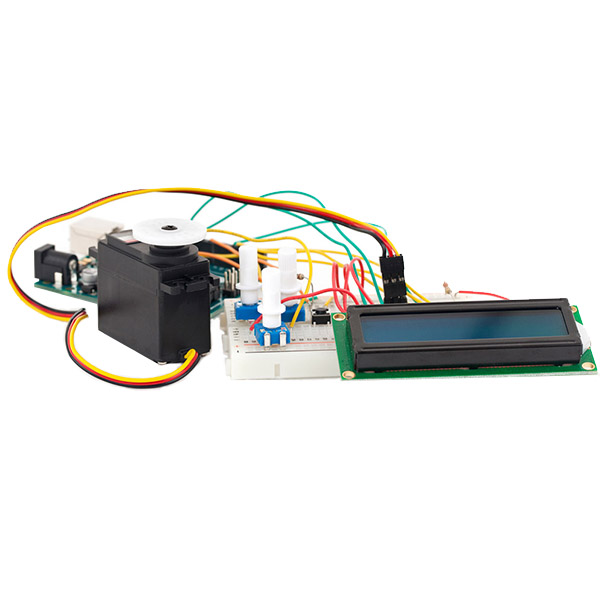

| Part Name | Small precision servo steering gear cover |

| Mould Cavity | 1*2 |

| Runner | Cold runner for sub gate |

| Standard | DME |

| Mould Material | S136/S50C/S-7/BeCU |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 25 days |

| Mould Cycle Time: | 25′s |

| Payment | T T |

Application field

In industrial type servo motors the position feedback sensor is usually a high precision encoder, while in the smaller RC or hobby servos the position sensor is usually a simple potentiometer. The actual position captured by these devices is fed back to the error detector where it is compared to the target position. Then according to the error the controller corrects the actual position of the motor to match with the target position.

Hobby servos are small in size actuators used for controlling RC toys cars, boats, airplanes etc. They are also used by engineering students for prototyping in robotics, creating robotic arms, biologically inspired robots, humanoid robots and so on.

The potentiometer is attached on the final gear or the output shaft, so as the motor rotates the potentiometer rotates as well, thus producing a voltage that is related to the absolute angle of the output shaft. In the control circuit, this potentiometer voltage is compared to the voltage coming from the signal line. If needed, the controller activates an integrated H-Bridge which enables the motor to rotate in either direction until the two signals reach a difference of zero.

A servo motor is controlled by sending a series of pulses through the signal line. The frequency of the control signal should be 50Hz or a pulse should occur every 20ms. The width of pulse determines angular position of the servo and these type of servos can usually rotate 180 degrees (they have a physical limits of travel).

Generally pulses with 1ms duration correspond to 0 degrees position, 1.5ms duration to 90 degrees and 2ms to 180 degrees. Though the minimum and maximum duration of the pulses can sometimes vary with different brands and they can be 0.5ms for 0 degrees and 2.5ms for 180 degrees position.

Project Management

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Fixed Competitive Price China High Precision Molding Inject Plastic Injection Molding Mold Customized Nylon Plastic Part, We sincerely expect exchange and cooperation with you. Let us move forward hand in hand and achieve win-win situation.

Fixed Competitive Price China Customized Nylon Plastic Part, High Precision Molding, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.