factory Outlets for China plastic mold

Adhering to the principle of “quality, service, efficiency and growth”, we have gained trusts and praises from domestic and international client for factory Outlets for China plastic mold, We’ll continue to keep doing work hard and as we try our greatest to offer the most effective good quality merchandise, most aggressive cost and excellent services to every customer. Your gratification, our glory!!!

Adhering to the principle of “quality, service, efficiency and growth”, we have gained trusts and praises from domestic and international client for factory Outlets for China plastic mold, With the advanced workshop, specialist design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our solutions are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

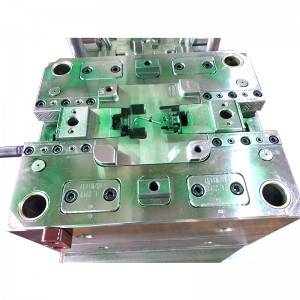

| Mould NO. | CPM-191018 |

| Surface Finish Process | Polish-#600 |

| Plastic Material | PC |

| Part weight | 1.5 g |

| Design Software | UG |

| Part size | 32.00 X 18.50 X 18.1 mm |

| Customized | Customized |

| Application | Electronic |

| Mould size | 296 X 346 X 326 mm |

| Mould Name | Angle buffer |

| Mould Cavity | 1*2(Use exchangeable insert to get four parts) |

| Runner | cold runner for Side gate |

| Standard | Hasco |

| Mould Material | 1.2343/1.2312/1.2767 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 38 days |

| Mould Cycle Time: | 27′s |

| Payment | T T |

Project Management

We have 12 Design Engineers with an average of 10 years design experience and a technical college level of education. The team will discuss every new project together and find the perfect solution for it, based on our knowledge and successful experience. We use 3D software to design the mold and Moldflow to verify and optimize the design, so that we can ensure it’s success.

After receiving your PO and part print, we will discuss and recommend any changes we think are necessary to make the part mouldable. We will then provide you with a DFM design report within two days to one week for you to review. We will discuss and then submit the part demoulding method and finalized mould design for your approval, before purchasing and cutting the steel. This process guarantees that we fulfill all of your design requirements.

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Adhering to the principle of “quality, service, efficiency and growth”, Chapman maker have gained trusts and praises from domestic and international client for factory Outlets for China plastic mold manufacturing and injection production Good Price, We’ll continue to keep doing work hard and as we try our greatest to offer the most effective good quality merchandise, most aggressive cost and excellent services to every customer. Your gratification, our glory!!!

factory Outlets for China plastic injection project, With the advanced workshop, specialist design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our solutions are fast selling onto European and American markets