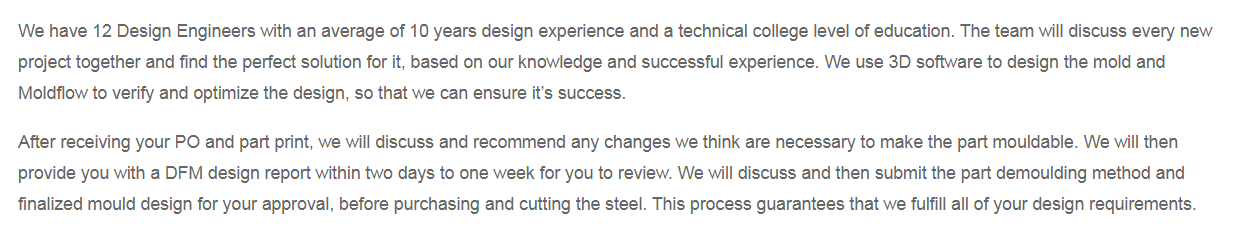

Best quality Plastic Mold Maker - Control Unit and Charge Connector bottom cover – Chapman

Best quality Plastic Mold Maker - Control Unit and Charge Connector bottom cover – Chapman Detail:

| Mould NO. | CPM-150239 |

| Surface Finish Process | VDI-36 |

| Plastic Material | ABS |

| Part weight | 231.65g |

| Design Software | UG/CAD |

| Part size | 242*120*98 mm |

| Customized | Customized |

| Application | Appliances |

| Mould size | 450 * 400 * 431mm |

| Part Name | Control Unit and Charge Connector bottom cover |

| Mould Cavity | 1*1 |

| Runner | point gate-three plate mould |

| Standard | LKM |

| Mould Material | NAK80/S50C |

| Mould Life Cycle | 500,000 |

| Lead Time | 35 days |

| Mould Cycle Time: | 42′s |

| Payment | T T |

Application field

Wall Connector continuously checks for the presence of a safe ground connection and automatically recovers from faults. Ground assurance operates by injecting a small amount of current into the ground

conductor in order to measure the impedance between line and ground.

Power sharing circuits may be installed in an electrical panel that supports other loads. If space is limited

or the main power supply is far from the Wall Connectors, installing a dedicated load center may be prudent.

As more Wall Connectors begin plugging into vehicles, the system will automatically distribute power based on the total power allocated to the site.

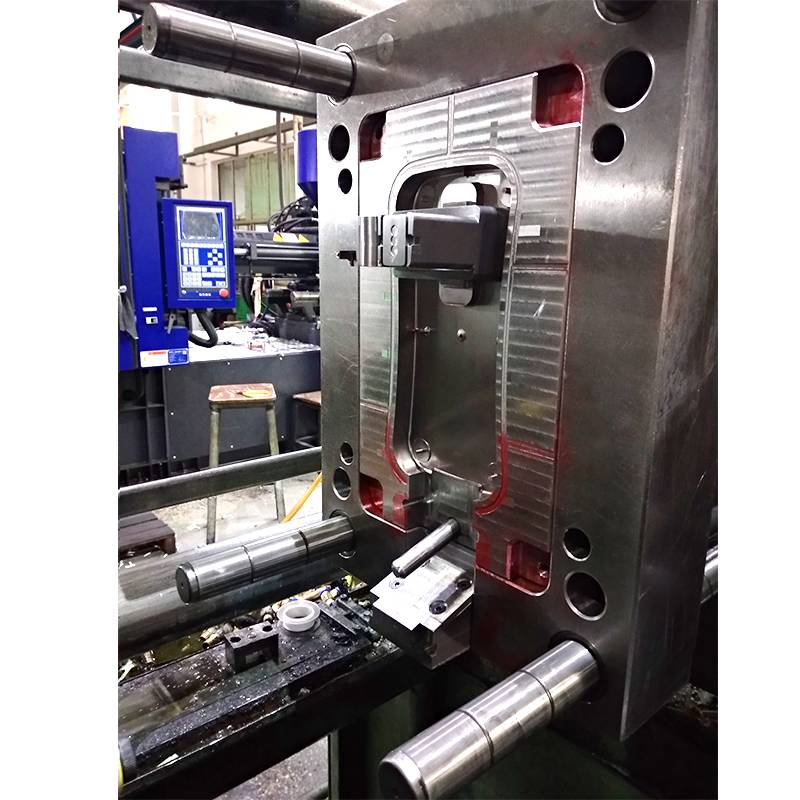

Project Management

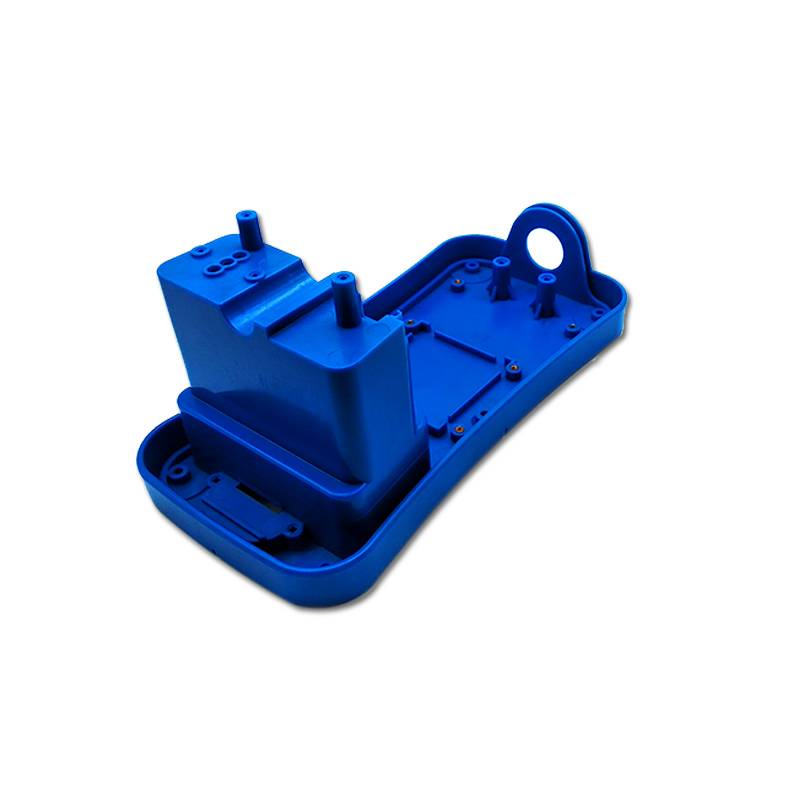

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for Best quality Plastic Mold Maker - Control Unit and Charge Connector bottom cover – Chapman , The product will supply to all over the world, such as: Algeria, Egypt, Greece, Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.