2020 Good Quality Plastic Injection - China 2K Mold Manufacturer – Chapman

2020 Good Quality Plastic Injection - China 2K Mold Manufacturer – Chapman Detail:

We’ve been proud of your substantial purchaser satisfaction and wide acceptance due to our persistent pursuit of high quality both equally on solution and service for China 2K Mold Manufacturer, Inside our initiatives, we already have a lot of shops in China and our solutions have won praise from buyers all over the world. Welcome new and outdated buyers to contact us to the long run long lasting business relationships.

We’ve been proud of your substantial purchaser satisfaction and wide acceptance due to our persistent pursuit of high quality both equally on solution and service for China Plastic Mould, Injection Mould, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We now have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our goods are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

| Mould NO. | CPM-150217 |

| Surface Finish Process | Polish-#600 |

| Plastic Material | PC+ABS |

| Part weight | 30.5g |

| Design Software | UG |

| Part size | 170.6*65.5*24.5 mm |

| Customized | Customized |

| Application | Electronic appliances |

| Mould size | 400 * 300 * 361mm |

| Part Name | Bank credit card POS machine |

| Mould Cavity | 1*1 |

| Runner | Three plate mould for point gate |

| Standard | DME |

| Mould Material | 1.2343ESU/1.2312/1.2767 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 30 days |

| Mould Cycle Time: | 36′s |

| Payment | T T |

Application field

Project Management

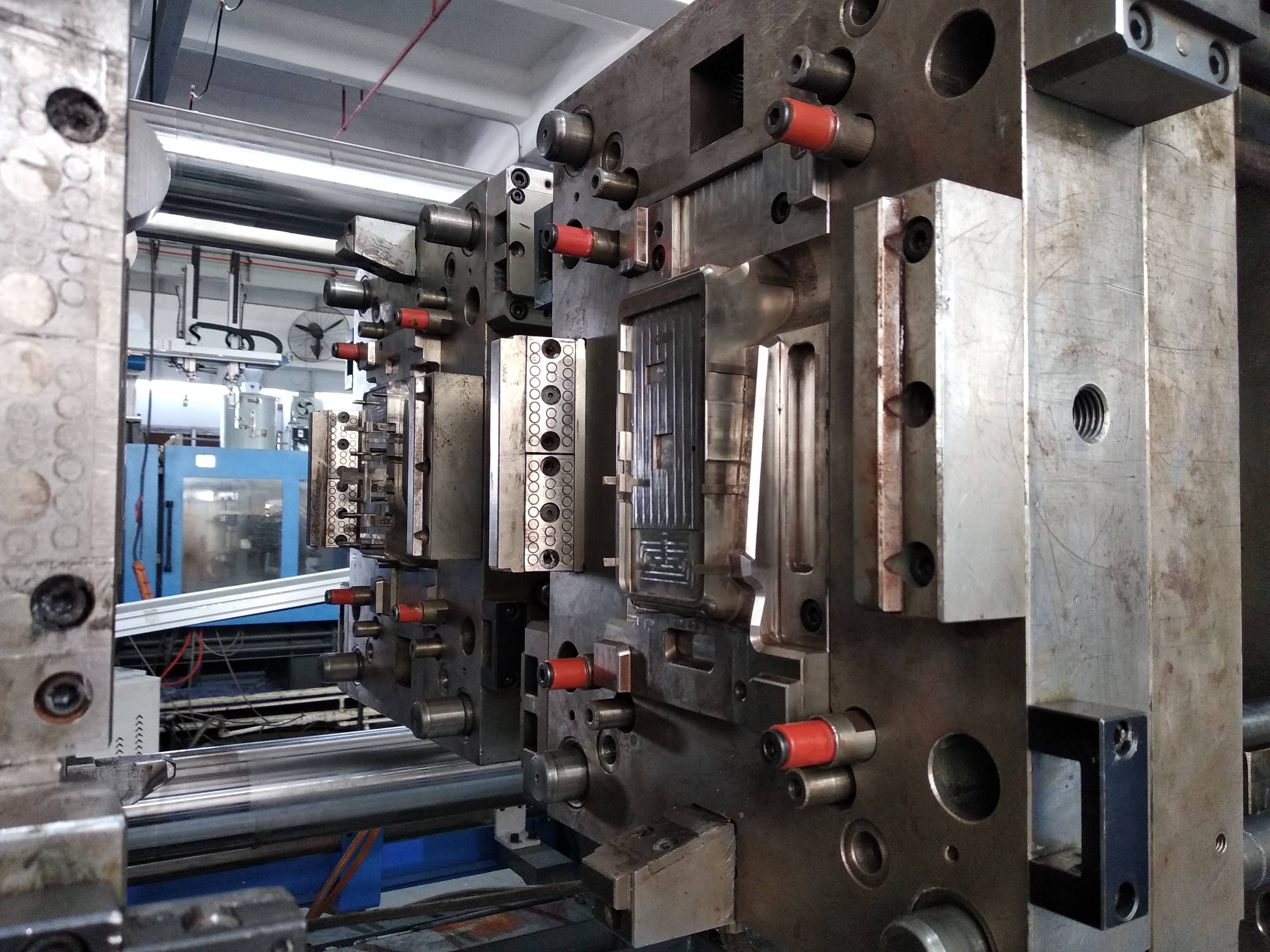

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

The plastic part of the shell is a part of the credit card POS machine. Its precision is high, and the matching position needs to be made within a tolerance of 0.1mm. Its material is PC+ABS fireproof V0 material.

This shell uses a two-color injection mold, which has very high requirements for mold accuracy and manufacturing. The mold material is NAK80, and the mold production cycle is 36 seconds.

The plastic shell of this POS machine was exported to a POS machine company in the United States. We have made more than 10 different POS machine housing parts for this customer, which have been well received by customers.

Product detail pictures:

Related Product Guide:

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for 2020 Good Quality Plastic Injection - China 2K Mold Manufacturer – Chapman , The product will supply to all over the world, such as: Serbia, Johannesburg, Sierra Leone, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!